Introduction: wiring harnesses as the backbone of safe appliances

Wiring harnesses are more than bundles of wires — they are engineered assemblies that organize conductors, connectors, and protective elements into a single, serviceable unit. In modern home appliances (washers, refrigerators, ovens, dishwashers, HVAC systems, and small kitchen appliances), harnesses improve both safety and reliability by controlling electrical pathways, reducing installation error, preventing mechanical damage, and simplifying testing and servicing. This article explains how harness design, material selection, assembly processes, and testing practices deliver measurable safety and reliability benefits for appliance manufacturers and end users.

Core design features that improve electrical safety

A well-designed harness prevents short circuits, reduces the risk of electric shock, and limits fire hazards. Key design features that deliver safety include proper conductor sizing, insulating jackets, separation of high- and low-voltage circuits, secure connector locking, and incorporation of protective devices such as fuses and thermal cutouts.

Conductor sizing and derating

Selecting the correct wire gauge for the expected current and ambient temperature is fundamental. Oversized conductors reduce overheating risk and voltage drop; derating for bundling, high ambient temperatures, and long run lengths ensures conductors remain below safe operating temperatures under real conditions. Proper gauge selection prevents insulation breakdown and prolonged thermal stress that would otherwise shorten lifespan.

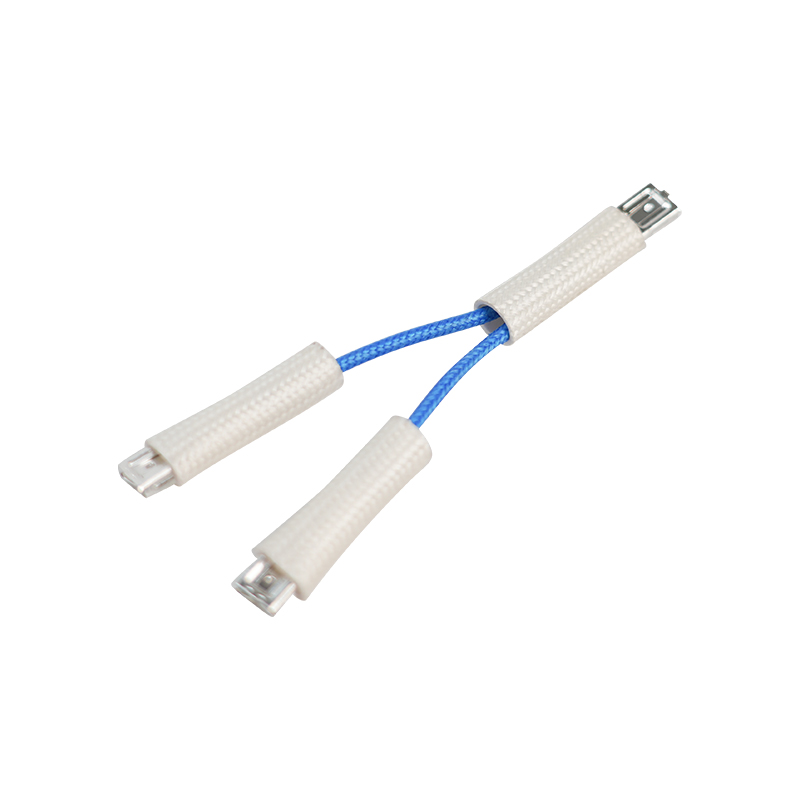

Insulation, jacketing, and flame-retardant materials

Insulation materials (PVC, cross-linked polyethylene, PTFE, silicone) are chosen for dielectric strength, temperature range, chemical resistance, and flame-retardant properties. Insulated harnesses use outer jacketing and sometimes braided sleeves to protect against abrasion, oil, and mechanical chafing — primary causes of exposed conductors and short circuits in appliances.

Circuit separation and shielding

Separating mains and control circuits reduces the chance of cross-faults; routing and different color-coding minimize assembly errors. For appliances with sensitive electronics, shielding or twisted pairs are added to harnesses to control electromagnetic interference (EMI), preventing malfunction and false triggering that could cause unsafe operation.

Mechanical features that increase reliability

Mechanical robustness addresses vibration, movement, water exposure, and user handling. Reliability comes from harness strain reliefs, secure termination methods, optimized routing, and the use of grommets and seals at enclosure entry points.

Crimps, terminals, and connector integrity

Quality crimping produces a gas-tight electrical and mechanical joint. Poor crimps cause intermittent resistance increases, heating, and eventual failure. Using validated crimp tools, controlled force, and inspection (pull tests, optical checks) ensures terminals resist vibration and thermal cycling. Locking connectors and secondary retention features reduce accidental disengagement during service or transport.

Strain relief, routing, and vibration mitigation

Strain reliefs (molded boots, clamps) and proper routing prevent stress concentrations near terminations. Harnesses routed away from moving parts and heat sources maintain insulation integrity. For compressors, motors, and pumps, vibration-damping clips and service loops allow movement without pulling on connections or abrading insulation.

Manufacturing controls and assembly best practices

Controlled assembly processes and factory controls transform a theoretical safe harness into a repeatable, reliable product. Standardized work instructions, fixture-based assemblies, operator training, and in-process inspections cut human error.

Harness layout and harness boards

Using harness boards (layout fixtures) ensures consistent wire lengths, correct connector positions, and repeatable crimp locations. This reduces field faults caused by misrouting or improperly-sized leads, improving first-pass assembly yields and downstream reliability.

Process validation and quality assurance

Statistical process control (SPC), pull-force testing, crimp cross-section audits, and connector mating cycle tests are routine quality checks. Traceability through barcode or lot marking makes it possible to quarantine suspect batches rapidly, protecting consumers and enabling corrective actions.

Testing protocols that verify safety and reliability

Testing is the final defense against defective harnesses. Several electrical and environmental tests confirm harness performance under expected and stress conditions.

- Continuity and polarity checks to ensure correct wiring and absence of opens.

- Insulation resistance and hipot testing to confirm dielectric strength and detect weak insulation that could arc under surge conditions.

- Voltage/current load tests to confirm thermal performance at rated currents.

- Environmental testing (thermal cycling, humidity, salt spray where relevant) to validate long-term reliability in real-world home environments.

- Vibration and mechanical shock testing, especially for appliances with moving parts, to confirm connector retention and conductor fatigue life.

Standards and regulatory compliance

Adherence to industry standards (UL in North America, IEC internationally, and regional safety agency requirements) ensures harnesses meet minimum safety thresholds. Standards cover flame resistance, current carrying capability, connector safety, and labeling. Manufacturers that design harnesses to exceed applicable standards reduce recall risk and demonstrate due diligence in safety engineering.

How harnesses reduce common appliance failure modes

Understanding failure modes clarifies how harnesses make appliances safer and longer-lived. Common failure modes include insulation abrasion, connector loosening, thermal overstress, and incorrect user/service reconnections. Harness features mitigate each of these:

| Failure Mode | Harness Design Response | Safety/Reliability Benefit |

| Abrasion / chafing | Sleeves, jacketing, routing away from sharp edges | Prevents exposure, short circuits, fire risk |

| Connector disengagement | Locking latches and secondary retention | Maintains circuit continuity and control integrity |

| Thermal overload | Correct gauge, fuses, thermal cutouts | Prevents overheating and fire |

Installation and service practices that preserve harness safety

Even the best harness can be compromised by poor installation or careless servicing. Clear routing diagrams, color-coded wiring, keyed connectors, and labelled harnesses reduce assembly errors in manufacturing and during field service. Service loops and detachable sub-harnesses help technicians replace modules without stressing other connections.

- Label critical harness branches (mains, earth, control) and include polarity markers where appropriate.

- Specify torque and pull forces for captive fasteners and connectors to prevent over- or under-tightening.

- Provide replacement harness part numbers and clear instructions for field repair versus replacement.

Checklist: what manufacturers should require for safe harnesses

A concise checklist helps engineering and quality teams ensure harnesses meet safety and reliability goals.

- Specification of wire gauges, insulation types, and temperature ratings for each harness branch.

- Defined connector types, mating cycles, locking mechanisms, and environmental sealing where required.

- Documented assembly process, crimp tool specifications, and inspection frequency.

- Testing plan that includes continuity, hipot, thermal/EMI exposure, and mechanical stress tests.

- Traceability and labeling policy for tracking harness batches and field failures.

Conclusion: measurable gains in safety and longevity

When properly specified, manufactured, and tested, wiring harnesses transform the electrical architecture of home appliances. They reduce human error, protect against mechanical and thermal damage, improve serviceability, and provide a structured path for regulatory compliance. For manufacturers, investing in engineered harness solutions lowers warranty costs and recall risk. For end users, harness-driven safety means fewer failures, reduced fire and shock hazards, and longer appliance life — a clear win for reliability and peace of mind.

English

English عربى

عربى Español

Español