High temperature and high voltage resistant silicone rubber motor lead wire is a cable designed for extreme environments, mainly used for electrical connections...

High Voltage Machine Lead Wire Manufacturers

-

-

JG3000V High Voltage Silicone Motor Lead Wire

JG3000V High Voltage Silicone Motor Lead WireThe JG3000V High Voltage Silicone Motor Lead Wire is engineered to deliver exceptional performance in the most demanding conditions. Featuring a temperature ran...

-

JG6000v Cqc Certified High Voltage Silicone Rubber Motor Lead Wire

JG6000v Cqc Certified High Voltage Silicone Rubber Motor Lead WireJG6000V CQC certified high voltage silicone rubber motor lead wire is built to excel in medium-to-high voltage applications (500V–10kV) , combining robust engin...

-

JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead Wire

JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead WireThe JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead Wire is a premium solution designed to meet the demands of industries where...

-

JYJ125 JYJ150 500v Irradiation Cross-Linked Xlpo Insulated Motor Lead Wire

JYJ125 JYJ150 500v Irradiation Cross-Linked Xlpo Insulated Motor Lead WireJYJ irradiation cross-linked motor lead wire is a common motor lead wire: 1. Materials and processes- Conductor: high-purity oxygen-free copper or tinned copper...

-

JYJ125 1000v High Voltage Resistant Radiation Cross-Linked Xlpo Motor Lead Wire

JYJ125 1000v High Voltage Resistant Radiation Cross-Linked Xlpo Motor Lead WireThe JYJ125 1000V high voltage resistant radiation cross-linked XLPO motor lead wire is designed to deliver unmatched performance in demanding industrial environ...

High voltage machine lead wire is an important part of connecting high-voltage motors to power supplies or other electrical equipment, and is usually able to withstand high voltage and high current.

Conductor material:

1. Copper core is commonly used. Copper has the advantages of good conductivity and high mechanical strength.

2. Insulation material: It needs to be resistant to high temperature and high voltage. Common materials include: cross-linked polyethylene (XLPE) and silicone rubber.

3. Insulation level: 1KV~10KV

4. Shielding layer: A shielding layer can be added to reduce electromagnetic interference and electric field concentration. Copper tape or copper wire is commonly used for weaving.

Installation and maintenance: Avoid excessive bending, maintain appropriate spacing, and prevent mechanical damage. Regularly check insulation, joints and shielding layers, and replace aging or damaged parts in time.

Application areas: Industry, power, mining, etc., such as motor connections for fans, compressors and other equipment. Used for N-class, F-class, and H-class motor winding lead wires.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

How does Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd.'s High Voltage Machine Lead Wire deal with voltage spikes or surges commonly found in high-voltage machinery?

In the realm of high - voltage machinery, voltage spikes and surges are persistent threats that can disrupt operations, damage equipment, and pose safety risks. Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd., a leading figure in the electrical cable and wire industry, has developed sophisticated solutions to safeguard against these challenges with its high voltage machine lead wires.

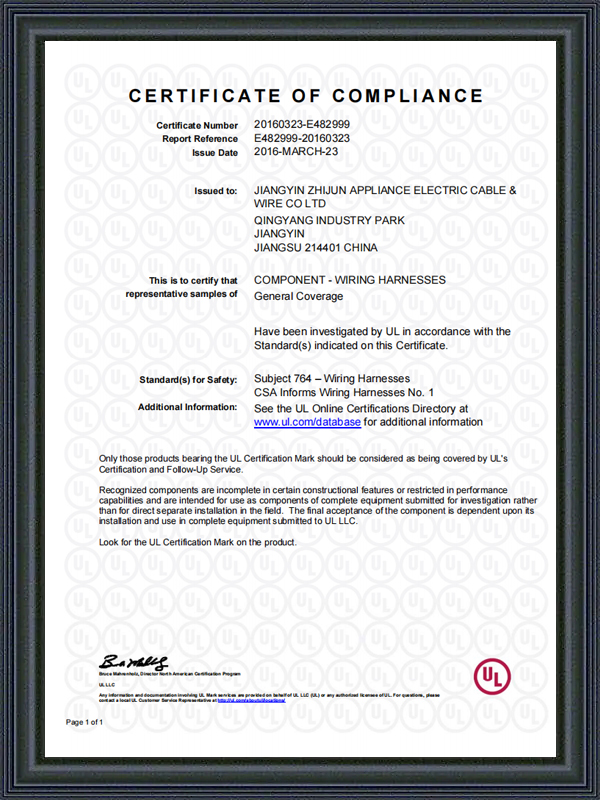

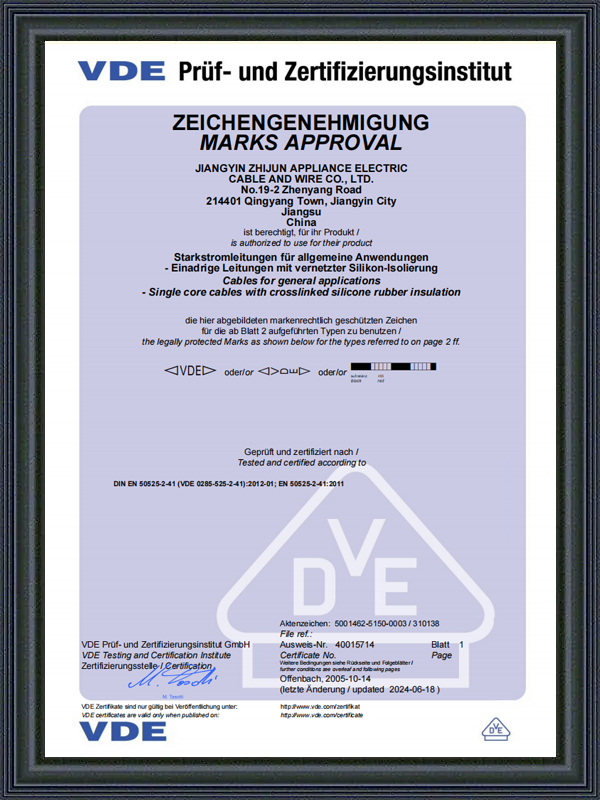

Company Introduction

Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. has a remarkable history and a strong standing in the market. Located at 19 Zhenyang Road, No. 2, Jiangyin City, Wuxi City, Jiangsu Province, the company has been at the forefront of the industry for decades. With a factory area of over 20,000 square meters and a workforce of more than 200 employees, including a dedicated technical team of 30 professionals, the company is well - equipped to meet the demands of modern manufacturing.

Founded in 1989 as a rubber products factory,it transformed into Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. in 2003 under the leadership of Ma Zhijun. Over the years, it has evolved into a high - tech enterprise with a dominant position in the industry and ranks among the top five high - temperature cable production bases in the country. The company has established strong technical cooperation with renowned research institutions such as the Shanghai Cable Research Institute, Shanghai Electrical Apparatus Research Institute, and Shanghai Rubber Research Institute of the Ministry of Machinery, ensuring continuous innovation and technical superiority.

Product Features and Solutions for Voltage Spikes and Surges

Superior Conductor Design

Jiangyin Zhijun's high voltage machine lead wires commonly use copper cores. Copper's excellent conductivity allows for efficient transmission of electrical energy, minimizing the resistance that could potentially cause overheating during voltage surges. Additionally, its high mechanical strength ensures that the conductor remains intact even when subjected to the sudden stress associated with voltage spikes. This combination of properties helps to maintain a stable electrical connection, reducing the risk of wire breakage or electrical arcing that could be triggered by voltage irregularities.

Advanced Insulation Technology

Insulation Material Selection

The company employs insulation materials like cross - linked polyethylene (XLPE) and silicone rubber, which are highly resistant to high temperature and high voltage. XLPE, with its outstanding thermal stability and dielectric strength, can withstand the intense heat generated during voltage spikes. Silicone rubber, on the other hand, not only offers high - temperature resistance but also has excellent flexibility and resistance to ozone and weathering. In high - voltage machinery, where voltage surges can lead to rapid temperature increases, these insulation materials maintain their integrity, preventing electrical leakage and short - circuits.

Insulation Level

With an insulation level ranging from 1KV to 10KV, the lead wires are designed to handle the normal operating voltages of high - voltage machinery with a significant safety margin. During voltage spikes or surges, the insulation can withstand the temporary over - voltage conditions without breaking down. This high - level insulation acts as a reliable barrier, protecting the conductor and surrounding components from the harmful effects of excessive voltage.

Shielding for Protection

Shielding Layer Function

A shielding layer is an integral part of Jiangyin Zhijun's high voltage machine lead wires. Made of materials such as copper tape or woven copper wire, the shielding layer serves multiple purposes in dealing with voltage spikes and surges. Firstly, it helps to reduce electromagnetic interference (EMI) generated during voltage fluctuations. Voltage spikes can produce strong electromagnetic fields that can disrupt the operation of nearby electrical and electronic equipment. The shielding layer acts as a Faraday cage, redirecting these electromagnetic waves away from sensitive components.

Secondly, it addresses electric field concentration. During voltage surges, the electric field around the conductor can become unevenly distributed, leading to areas of high electric field strength. The shielding layer helps to distribute the electric field more evenly, preventing localized over - stress on the insulation and reducing the risk of insulation breakdown.

Installation, Maintenance, and Quality Assurance

Proper Installation

The company emphasizes proper installation techniques to minimize the impact of voltage spikes and surges. Installers are trained to avoid excessive bending of the lead wires, as this can weaken the conductor and insulation, making them more vulnerable to voltage - related damage. Maintaining appropriate spacing from other conductive materials or heat sources is also crucial. In high - voltage machinery, where voltage spikes can cause arcing, proper spacing reduces the likelihood of electrical discharges between components.

Regular Maintenance

Jiangyin Zhijun recommends regular maintenance of the high voltage machine lead wires. This includes checking the insulation for any signs of wear, such as cracks or discoloration, which could be an indication of stress from voltage spikes. Inspecting joints for looseness or corrosion is also essential, as a poor connection can exacerbate the effects of voltage surges. By regularly maintaining the lead wires, potential issues can be detected and addressed before they lead to major failures.

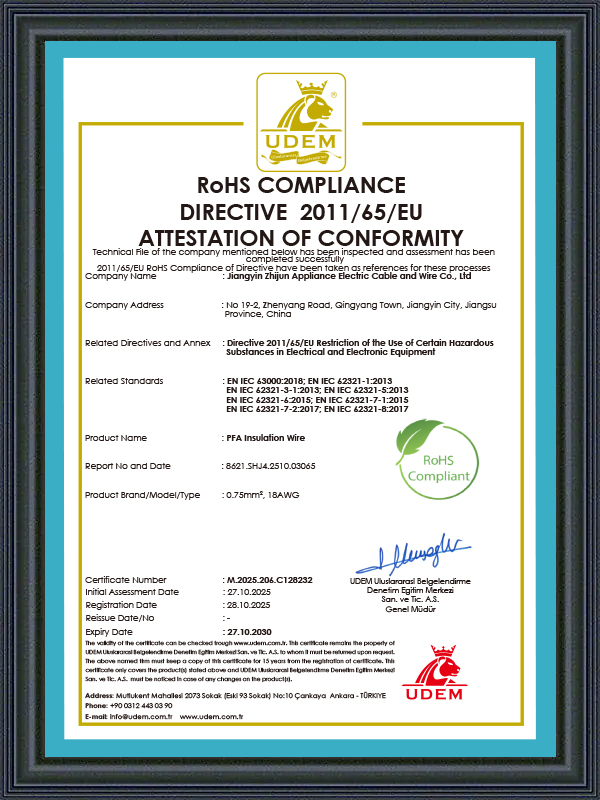

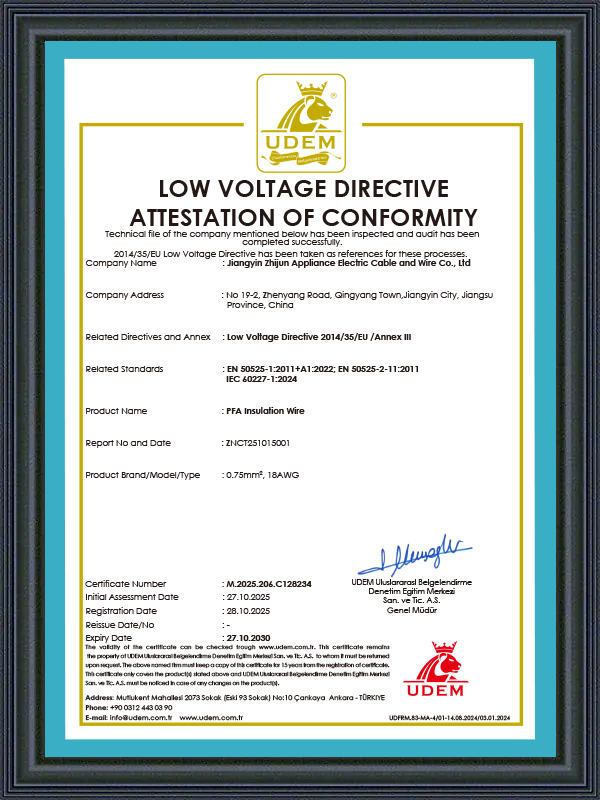

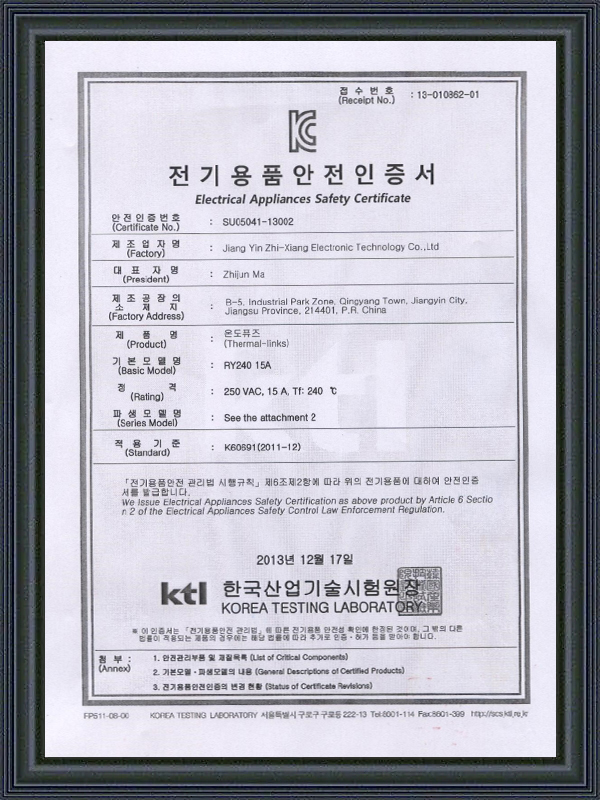

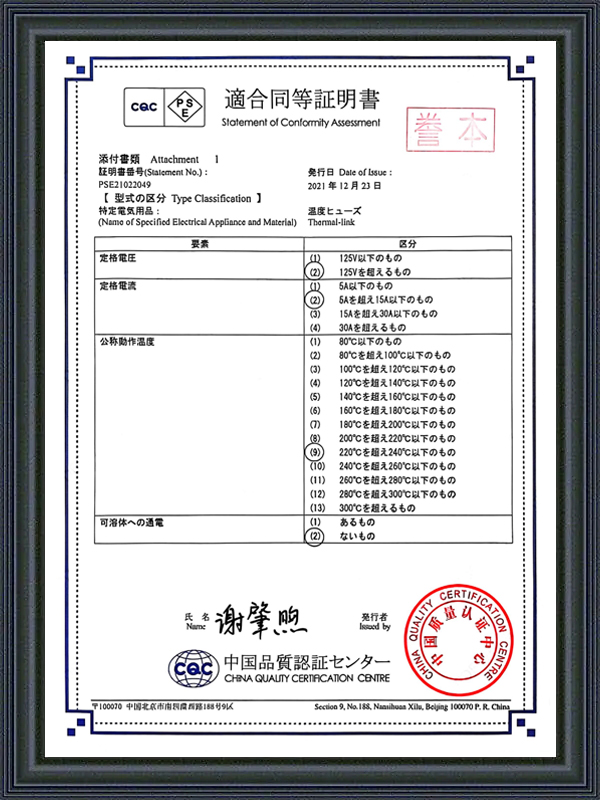

Quality Assurance System

The company has a rigorous quality assurance system in place. From the selection of raw materials to the final product inspection, every step of the production process is closely monitored. All products are tested to ensure they meet or exceed industry standards, and a comprehensive traceability system allows for the tracking of each product's production history. This ensures that in the rare event of a problem related to voltage spikes or surges, the root cause can be quickly identified and resolved.

Applications and Success Stories

Jiangyin Zhijun's high voltage machine lead wires are widely used in industries such as power, mining, and manufacturing. In power plants, for example, where high - voltage motors are used to drive generators and other critical equipment, the lead wires' ability to handle voltage spikes and surges ensures the stable operation of the entire power generation system. In mining, high - voltage machinery is often subjected to harsh operating conditions, including voltage fluctuations due to the nature of the electrical supply in remote areas. The company's lead wires have proven reliable in such environments, minimizing downtime and maintenance costs.

Over the years, the company has supplied its products to numerous well - known brands, including Midea, Joyoung, Gree, Haier, TCL, Supor, Hisense,etc. These partnerships are a testament to the quality and reliability of Jiangyin Zhijun's products, especially their ability to perform under challenging electrical conditions such as voltage spikes and surges.

In conclusion, Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd.'s high voltage machine lead wires are engineered with a combination of advanced materials, innovative design, and strict quality control to effectively deal with voltage spikes and surges commonly found in high - voltage machinery. Their products not only ensure the safe and efficient operation of high - voltage equipment but also contribute to the overall reliability of industrial electrical systems.

English

English عربى

عربى Español

Español