JYJ irradiation cross-linked motor lead wire is a common motor lead wire: 1. Materials and processes- Conductor: high-purity oxygen-free copper or tinned copper...

Irradiation Cross-Linked Motor Lead Wire Suppliers

-

-

JYJ125 1000v High Voltage Resistant Radiation Cross-Linked Xlpo Motor Lead Wire

JYJ125 1000v High Voltage Resistant Radiation Cross-Linked Xlpo Motor Lead WireThe JYJ125 1000V high voltage resistant radiation cross-linked XLPO motor lead wire is designed to deliver unmatched performance in demanding industrial environ...

Irradiation cross-linked motor lead wire is a motor lead wire that is cross-linked by irradiation technology and is mainly used for internal connection of the motor. The following is a detailed introduction to irradiation cross-linked motor lead wire:

1. Irradiation cross-linking technology

Irradiation cross-linking is the use of high-energy rays (such as electron beams or gamma rays) to irradiate polymer materials to form a cross-linked structure between their molecular chains, thereby improving the heat resistance, mechanical strength and chemical stability of the material. This technology does not require chemical cross-linking agents, is environmentally friendly and efficient.

2. Lead wire characteristics

- High temperature resistance: The material after irradiation cross-linking can remain stable at high temperatures and is suitable for high temperature environments.

- High mechanical strength: The cross-linked structure enhances the tensile strength and wear resistance of the material.

- Excellent electrical properties: Good insulation performance, excellent voltage resistance and arc resistance.

- Chemical stability: Oil resistance, solvent resistance and corrosion resistance, suitable for complex environments.

- Environmental protection: No chemical cross-linking agent is required, and there are no harmful substances in the production process.

3. Application areas

- Industrial motors: used in high temperature, high humidity or corrosive environments.

- Household appliances: such as washing machines, air conditioners, etc., to improve safety and durability.

- Automotive motors: used in high-temperature areas such as engine compartments.

- Aerospace: used for high-temperature and radiation-resistant motor systems.

4. Manufacturing process

- Material selection: commonly used polyethylene (PE), polyvinyl chloride (PVC), etc.

- Irradiation treatment: through electron accelerator or gamma ray irradiation, a cross-linked structure is formed.

- Subsequent processing: including cooling, cutting, testing, etc. to ensure quality.

5. Advantages

- High performance: heat resistance, chemical corrosion resistance, excellent mechanical and electrical properties.

- Long life: cross-linked structure extends the service life.

- Environmental protection: The production process is pollution-free and meets environmental protection requirements.

6. Market prospects

With the growth of industrial automation and electrical demand, the demand for high-performance motor lead wires has increased. The irradiation cross-linking technology has broad market prospects due to its environmental protection and high efficiency. Irradiation cross-linked motor lead wires have been widely used in many fields due to their excellent performance and environmental protection characteristics. In the future, with the advancement of technology, its application scope will be further expanded.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

Irradiation Cross-Linked Motor Lead Wire has excellent stability in high temperature and high pressure environments

In the rapidly evolving world of electrical engineering and industrial manufacturing, the demand for reliable, high-performance wiring solutions has never been greater. Among the various specialized wire types available in today's market, irradiation cross-linked motor lead wire stands out as a revolutionary solution that offers exceptional stability in extreme operating conditions, particularly in high temperature and high pressure environments.

Understanding Irradiation Cross-Linking Technology

Irradiation cross-linking is an advanced manufacturing process that creates strong molecular bonds within polymer materials through exposure to high-energy radiation. This sophisticated technique transforms linear polymer chains into a three-dimensional network structure, dramatically enhancing the material's thermal stability, mechanical strength, and chemical resistance. The resulting cross-linked polymers exhibit superior performance characteristics that make them ideal for demanding applications in motors, automotive systems, and industrial equipment.

The cross-linking process fundamentally changes the molecular structure of the insulation material, creating covalent bonds between polymer chains that cannot be easily broken by heat or pressure. This molecular transformation results in materials that maintain their integrity even under extreme thermal cycling and mechanical stress conditions that would typically degrade conventional insulation materials.

Superior Performance in Extreme Conditions

Irradiation cross-linked motor lead wire demonstrates remarkable stability when exposed to high temperature environments, often maintaining performance at temperatures exceeding 150°C for extended periods. The cross-linked structure prevents thermal degradation and maintains electrical insulation properties even under continuous high-temperature operation. This makes the wire particularly suitable for applications in electric motors, transformers, and other electrical equipment that generate significant heat during operation.

In high-pressure environments, the enhanced mechanical properties of cross-linked materials provide superior resistance to compression and deformation. The three-dimensional molecular network structure distributes mechanical stress more effectively than linear polymers, preventing insulation damage and maintaining electrical performance integrity. This characteristic is especially valuable in applications such as submersible pumps, downhole drilling equipment, and high-pressure industrial systems.

Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd: A Leader in Advanced Wire Technology

With over 20 years of dedicated focus on research and development, Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd has established itself as a premier manufacturer of high-performance electrical wiring solutions. The company's extensive 20,000 square meter factory facility houses state-of-the-art production equipment and testing instruments, supported by a skilled technical team of 30 professionals and over 200 total employees.

The company's commitment to quality is evident through its rigorous quality assurance system and comprehensive traceability system, which ensure consistent product excellence. Jiangyin Zhijun's advanced production management system incorporates cutting-edge technology and best practices to deliver reliable, high-quality products that meet the most demanding industry standards.

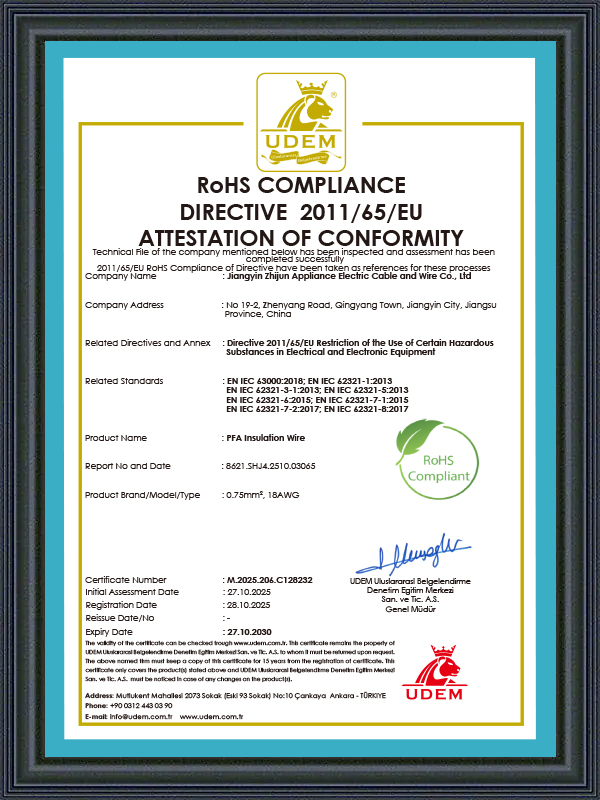

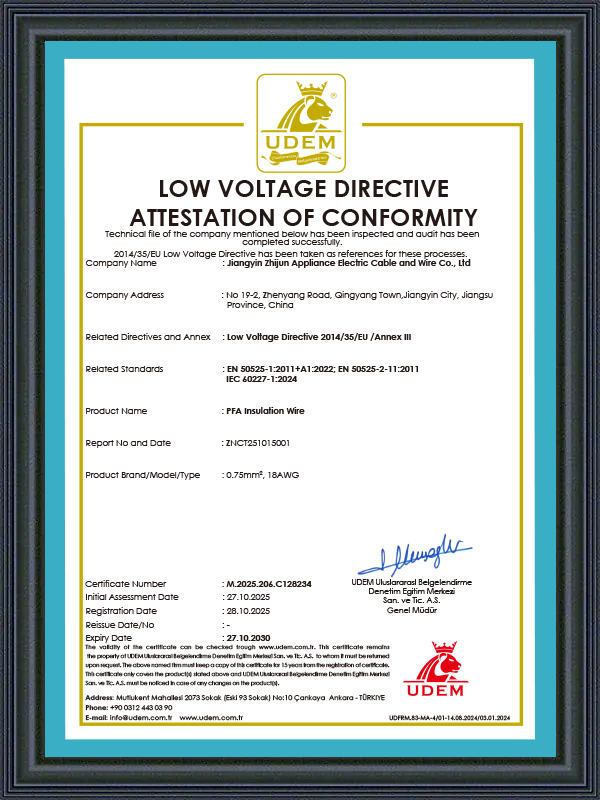

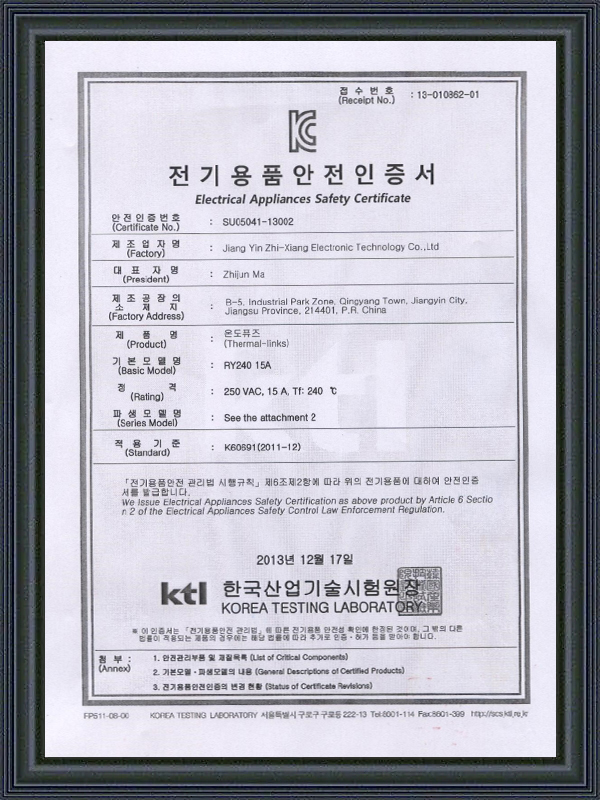

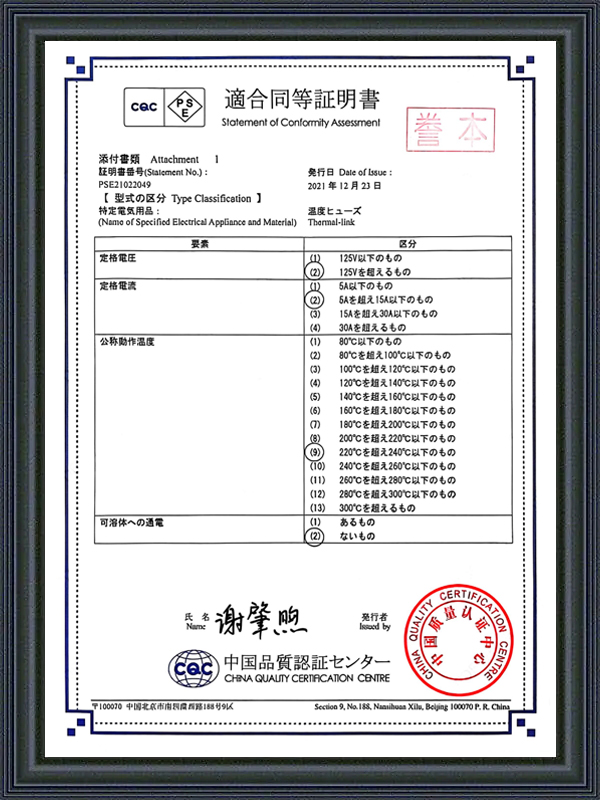

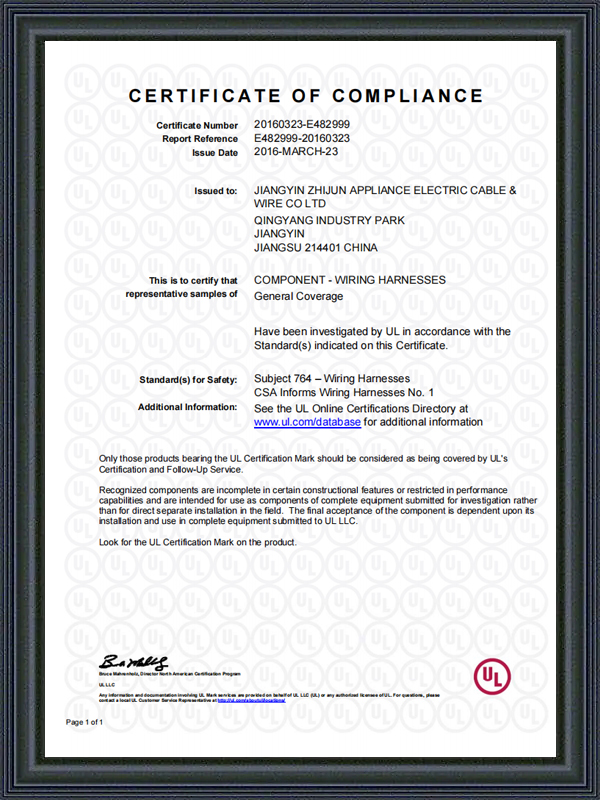

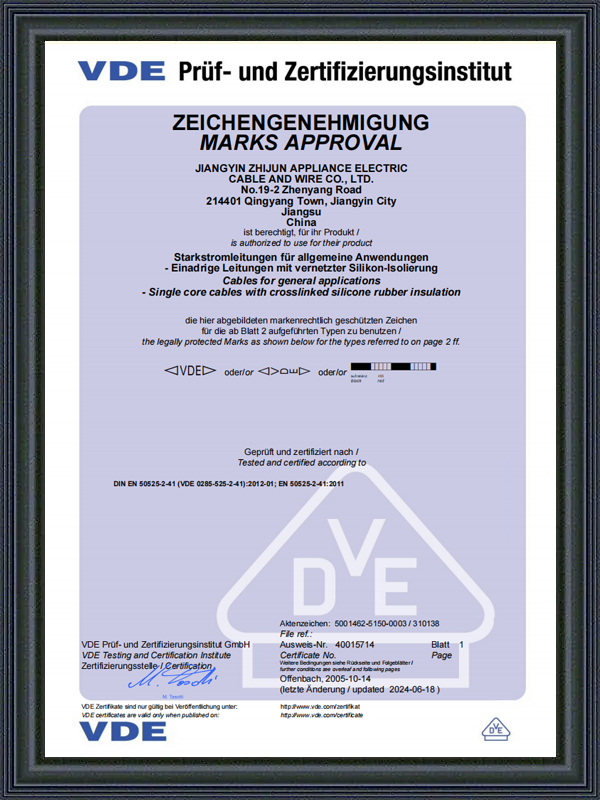

Comprehensive Product Certification and Industry Recognition

All products manufactured by Jiangyin Zhijun have achieved internationally recognized safety certifications, including UL, VDE, TUV, CCC, KC, PSE, ROHS, and REACH compliance. The company's ISO9001:2015 international quality management system certification further demonstrates its commitment to maintaining the highest standards of quality and customer satisfaction.

Jiangyin Zhijun's irradiation cross-linked wire products are specifically engineered to excel in challenging environments where conventional wiring solutions might fail. The company's expertise in silicone rubber series, PVC series, radiation crosslinking series, and Teflon series products has made it the preferred supplier for major brands including Midea, Jiuyang, Gree, Oxx, TCL, Supor, Tsinghua Tongfang, Ashta, Hisense, and SN.

Applications and Benefits

The exceptional stability of irradiation cross-linked motor lead wire makes it ideal for various critical applications. In electric motor manufacturing, these wires provide reliable performance in the high-temperature environment of motor windings while maintaining flexibility for easy installation. Automotive applications benefit from the wire's ability to withstand both high under-hood temperatures and the vibration and pressure variations common in vehicle operation.

Industrial equipment manufacturers rely on these specialized wires for applications involving high-pressure steam systems, hydraulic equipment, and high-temperature processing machinery. The long-term stability and reliability of cross-linked insulation significantly reduce maintenance requirements and equipment downtime.

Future Outlook

As industries continue to demand more robust and reliable electrical systems, irradiation cross-linked motor lead wire represents a critical technology for meeting these challenges. Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd remains committed to advancing this technology through continuous research and development, ensuring that their products continue to meet the evolving needs of global markets.

The company's mission to "create value for customers" drives innovation in high-temperature, high-pressure wire solutions, positioning Jiangyin Zhijun as a leading force in creating the most innovative and influential home appliance supporting enterprises in the industry.

English

English عربى

عربى Español

Español