High temperature and high voltage resistant silicone rubber motor lead wire is a cable designed for extreme environments, mainly used for electrical connections...

Silicone Rubber Motor Lead Wire Suppliers

-

-

JG3000V High Voltage Silicone Motor Lead Wire

JG3000V High Voltage Silicone Motor Lead WireThe JG3000V High Voltage Silicone Motor Lead Wire is engineered to deliver exceptional performance in the most demanding conditions. Featuring a temperature ran...

-

JG6000v Cqc Certified High Voltage Silicone Rubber Motor Lead Wire

JG6000v Cqc Certified High Voltage Silicone Rubber Motor Lead WireJG6000V CQC certified high voltage silicone rubber motor lead wire is built to excel in medium-to-high voltage applications (500V–10kV) , combining robust engin...

-

JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead Wire

JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead WireThe JG10000V National Standard Certified High Voltage Silicone Rubber Insulated Lead Wire is a premium solution designed to meet the demands of industries where...

Silicone rubber motor lead wire is a high-performance cable for motor connection, usually used in high temperature, high humidity, corrosive environment or occasions requiring good flexibility and electrical insulation performance. Here are some key features and applications of silicone rubber motor lead wire:

Features:

1. High temperature resistance: Silicone rubber material has excellent high temperature resistance and can usually withstand a temperature range of -60°C to +200°C. Some special models can even withstand higher temperatures.

2. Flexibility: Silicone rubber cable has good flexibility and is suitable for use in occasions that require frequent movement or bending.

3. Electrical insulation performance: Silicone rubber has excellent electrical insulation performance and can effectively prevent current leakage and short circuit.

4. Corrosion resistance: Silicone rubber has good corrosion resistance to most chemicals and is suitable for corrosive environments such as chemicals and petroleum.

5. Aging resistance: Silicone rubber material has excellent aging resistance and can maintain its physical and electrical properties in long-term use.

6. Flame retardant: Silicone rubber cable usually has flame retardant properties, which can slow down the spread of flames in the event of a fire.

Structure:

Silicone rubber motor lead wires are usually composed of the following parts:

1. Conductor: Copper or tinned copper conductors are usually used, which have good conductivity and corrosion resistance.

2. Insulation layer: Silicone rubber material is used to provide excellent electrical insulation and high temperature resistance.

3. Sheath layer: The outer sheath is also made of silicone rubber to further enhance the mechanical protection and environmental resistance of the cable.

Selection considerations:

1. Temperature range: Select the appropriate temperature resistance level according to the use environment.

2. Voltage level: Select the appropriate cable according to the voltage requirements of the motor.

3. Bending performance: If the cable needs to be moved or bent frequently, choose a model with better flexibility.

4. Flame retardant requirements: According to the safety requirements of the use environment, choose whether a flame retardant cable is required.

Since its excellent performance, silicone rubber motor lead wires are widely used in various high temperature, high humidity and corrosive environments, and are a high-end choice among motor connection wires.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

Can the Silicone Rubber Motor Lead Wire of Jiangyin Zhijun Electrical Cable Co., Ltd. withstand the oils, chemicals or solvents commonly found in motor environments?

In the complex environment where motors operate, the erosion of oils, chemicals and solvents is a common hidden danger that threatens the performance of cables, and the corrosion resistance of cables is directly related to the stable operation and service life of the motor system. For the Silicone Rubber Motor Lead Wire produced by Jiangyin Zhijun Electrical Cable Co., Ltd., their performance in dealing with such environmental challenges is not only due to the excellent properties of the silicone rubber material itself, but also due to the company's 20 years of intensive work in the field of high-temperature cables.

As a high-performance motor connection cable, one of the core advantages of Silicone Rubber Motor Lead Wire is its excellent corrosion resistance. Silicone rubber materials have a natural resistance to most chemicals, which enables them to maintain stable performance in motor environments filled with various oils, chemical reagents and solvents. Whether it is lubricating oil and hydraulic oil that may be exposed during motor operation, or acid and alkali solutions and organic solvents commonly found in industrial scenarios, the silicone rubber insulation layer and sheath layer can form an effective barrier to prevent cable aging, insulation failure or conductor corrosion caused by the penetration of these substances. This characteristic is not accidental. The stability of the molecular structure of silicone rubber makes it difficult to swell, crack or degrade when in contact with various chemicals, which fundamentally guarantees the electrical insulation performance and mechanical strength of the cable.

In addition to corrosion resistance, the comprehensive performance of this lead wire has laid a solid foundation for its application in harsh environments. It has high temperature resistance from - 60°C to + 200°C (some special models can withstand higher temperatures), and can maintain flexibility and insulation in the high temperature environment generated by the continuous operation of the motor; good flexibility enables it to adapt to frequent movement or bending conditions to avoid damage caused by mechanical stress; excellent electrical insulation performance effectively prevents current leakage and short circuit risks, and flame retardant properties further enhance the safety of the motor system. From a structural point of view, copper or tinned copper as the conductor ensures excellent conductivity and corrosion resistance, and the insulation layer and sheath layer of silicone rubber form double protection, which comprehensively enhances the environmental adaptability of the cable.

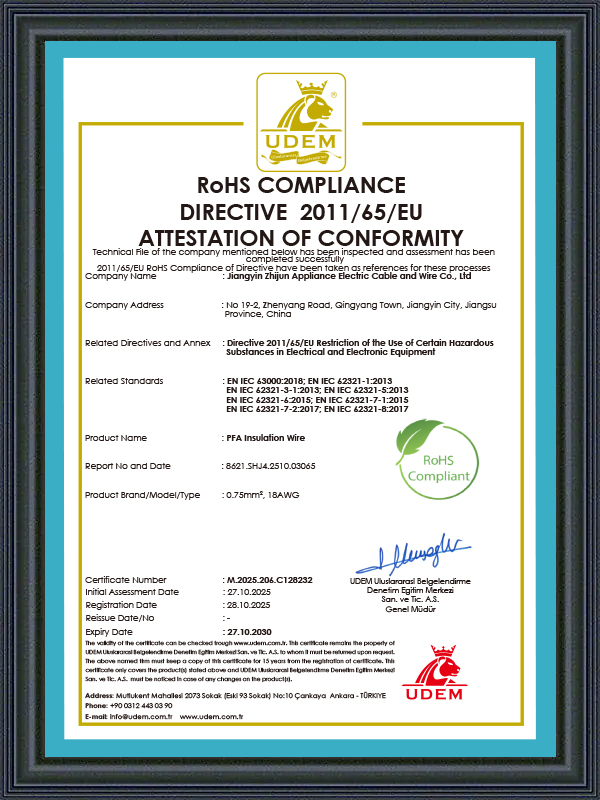

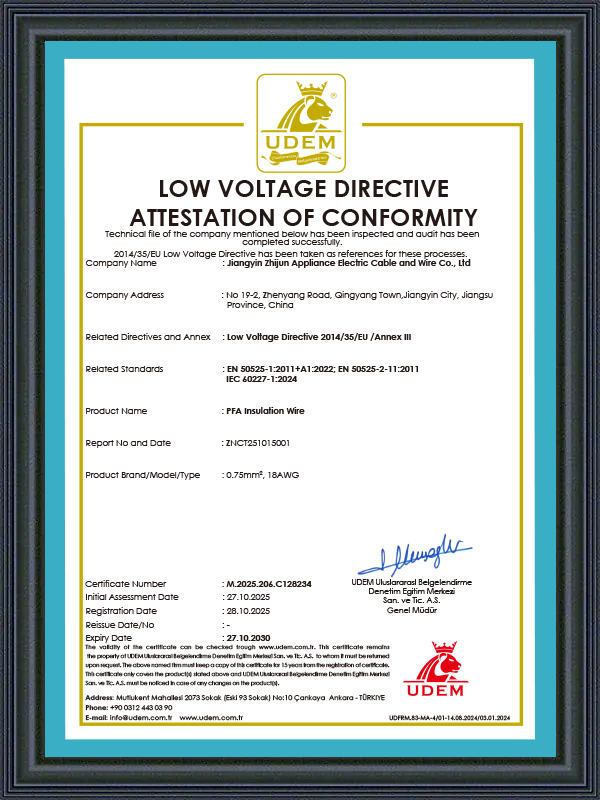

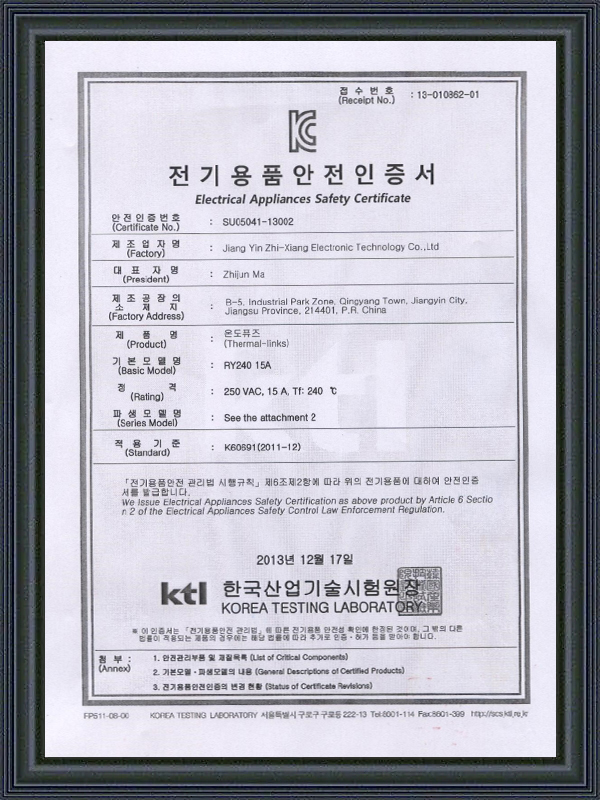

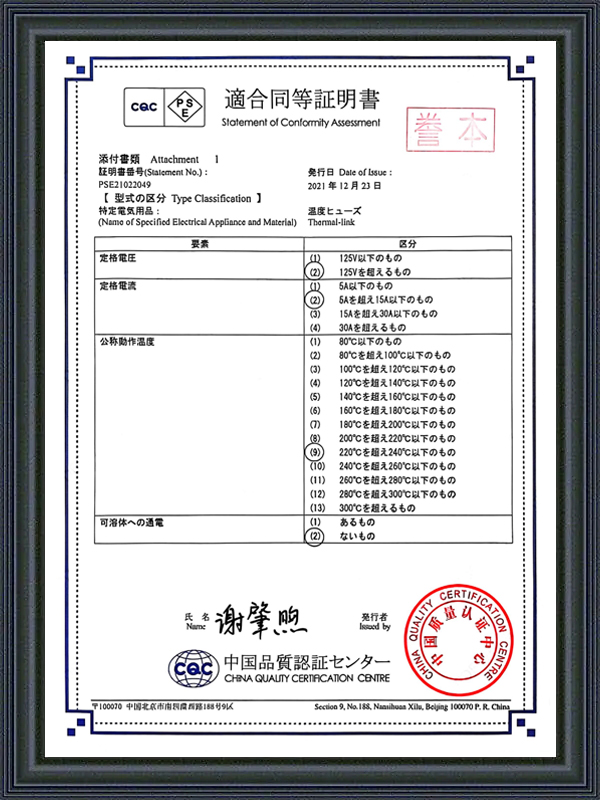

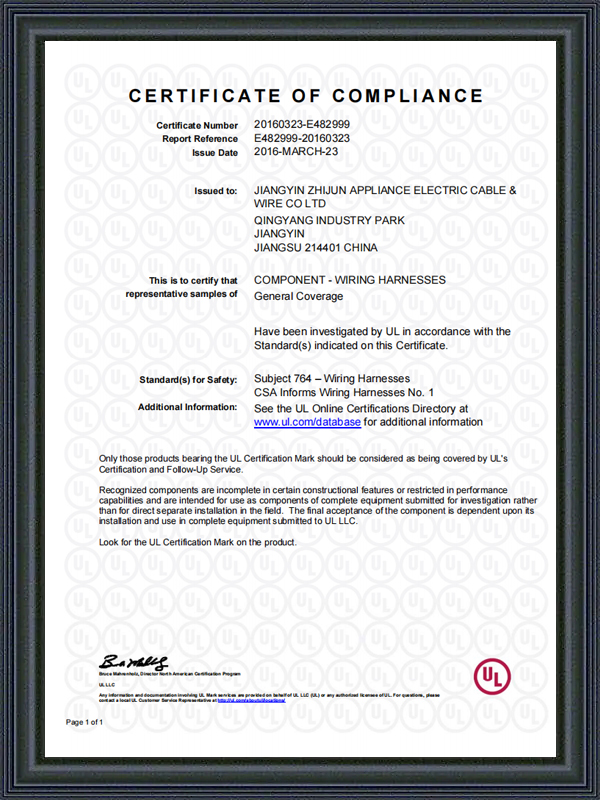

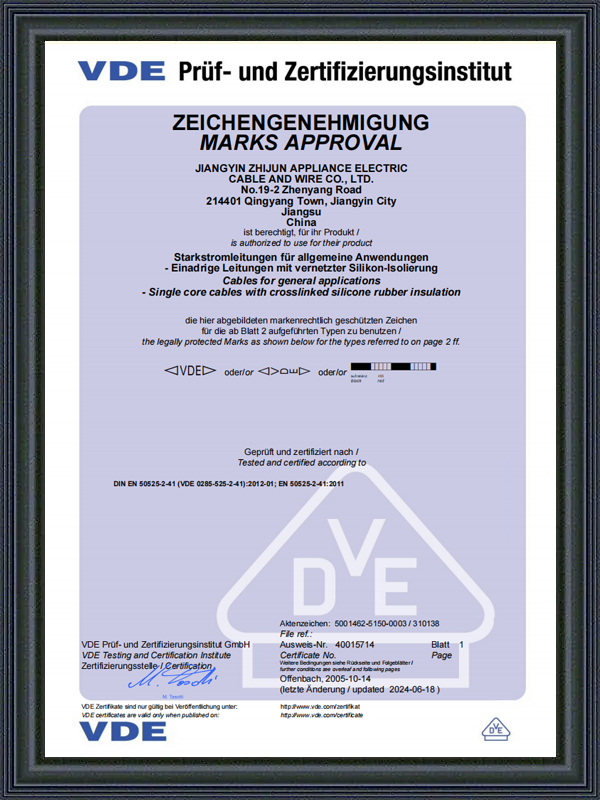

Such high-quality Silicone Rubber Motor Lead Wire come from the professional accumulation of Jiangyin Zhijun Electrical Cable Co., Ltd. The company has a plant area of nearly 20,000 square meters, more than 200 employees and a professional technical team of 30 people. It is equipped with advanced production management equipment and testing instruments, and has established a complete production management system, a rigorous quality assurance system and a traceability system. For 20 years, the company has focused on the research and development and production of various high-temperature resistant wires and internal wiring harnesses of small household appliances, such as silicone rubber series, PVC series, radiation cross-linking series, and polytetrafluoroethylene series. The products are widely used in electronics, electrical appliances, lighting, motors, automobiles and other industries. In terms of selection, the company can provide precisely adapted products according to the specific needs of customers such as temperature range, voltage level, bending performance and flame retardant requirements, ensuring that each cable can perform at its best in actual applications.

In summary, the silicone rubber motor lead of Jiangyin Zhijun Electrical Cable Co., Ltd., with the inherent advantages of silicone rubber materials and the company's professional manufacturing process, can effectively withstand the common oils, chemicals and solvents in the motor environment. It is a reliable choice for motor connection and provides a strong guarantee for the stable operation of various motor equipment.

English

English عربى

عربى Español

Español