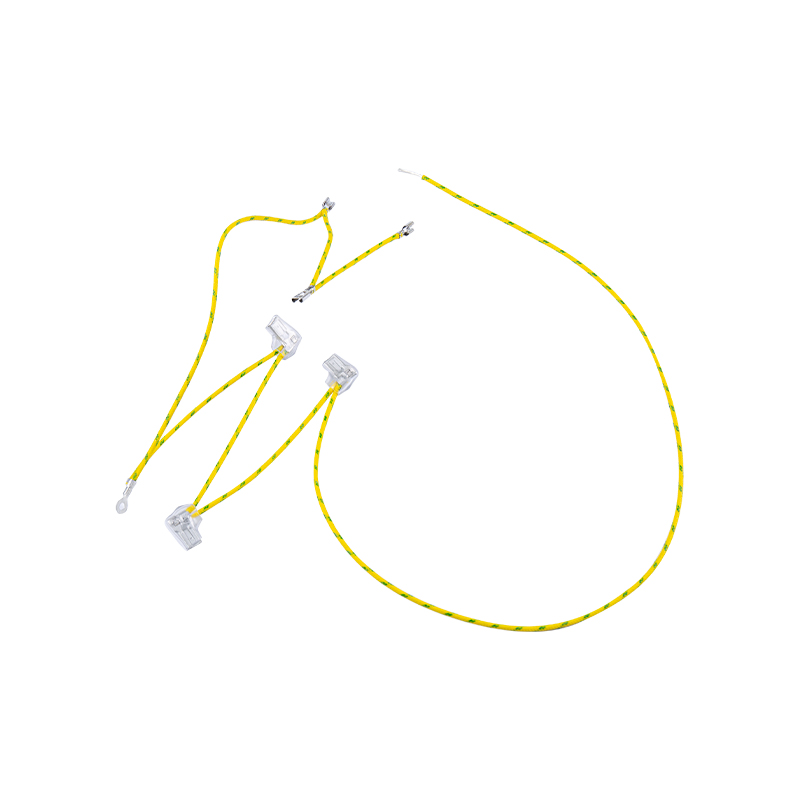

Bathroom Heater Internal Connection Wiring Harness is an indispensable key electrical component in the bathroom heating equipment. It is responsible for connect...

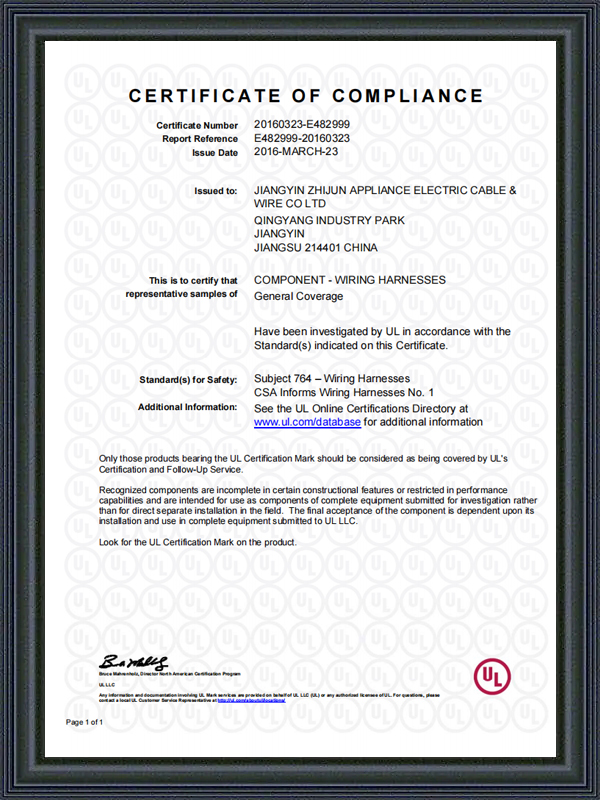

Household Appliances Wiring Harness Suppliers

-

-

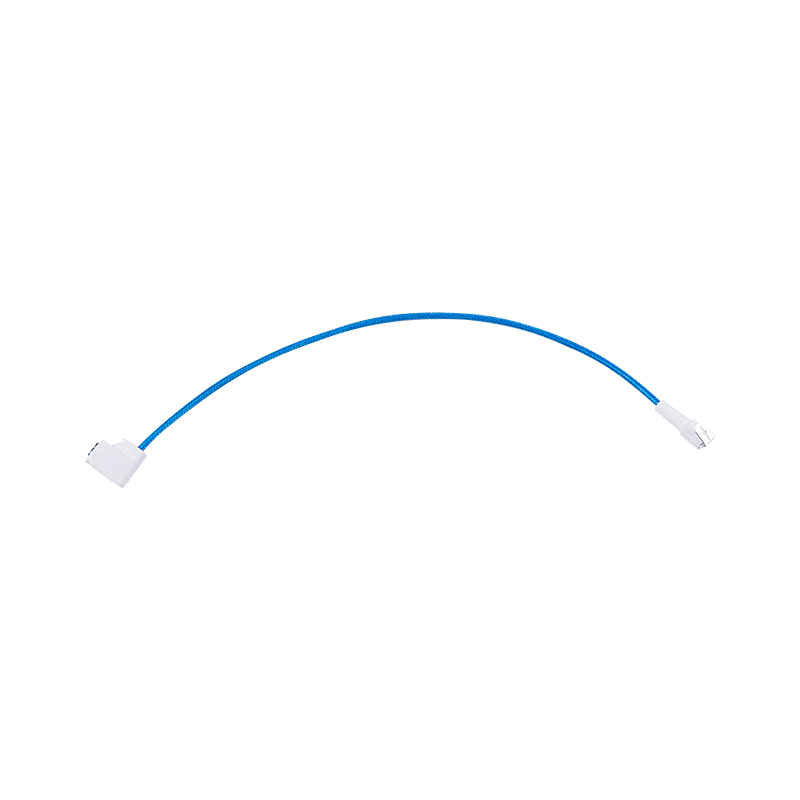

Smart Toilet Lid Internal Connection Wiring Harness

Smart Toilet Lid Internal Connection Wiring HarnessThe internal connection harness of the smart toilet seat is a key component in the electrical system of the smart toilet seat. It is responsible for organically...

-

Coffee Machine Internal Wiring Harness

Coffee Machine Internal Wiring HarnessThe internal wiring harness of the coffee machine is an important part of connecting the various electrical components of the coffee machine. It undertakes the ...

-

Sealing Machine Internal Connection Wiring Harness

Sealing Machine Internal Connection Wiring HarnessThe internal connection harness of the sealing machine is a key component of the electrical system of the equipment. It is responsible for connecting multiple m...

-

Milk Tea Machine Internal Connection Wiring Harness

Milk Tea Machine Internal Connection Wiring HarnessThe internal connection harness of the milk tea machine is an important part of the electrical system of the whole machine. It is responsible for connecting mul...

-

Vacuum Cleaner Internal Connection Wiring Harness

Vacuum Cleaner Internal Connection Wiring HarnessVacuum Cleaner Internal Connection Wiring Harness is an important part of the electrical system of the equipment. It is responsible for closely connecting the p...

Household appliances wiring harness refers to the wire harness used in household appliances. They are responsible for connecting the various electronic components inside the appliances to ensure the transmission of power and signal control. This type of wiring harness is widely used in various household appliances, such as washing machines, refrigerators, air conditioners, microwave ovens, vacuum cleaners, etc.

Main features

1. Safety: Household appliances wiring harness needs to meet strict safety standards to prevent safety hazards such as short circuits and overheating.

2. Durability: Due to the high frequency of use of household appliances, the wiring harness needs to have good durability and be able to withstand long-term use and certain mechanical stress.

3. Flexibility: The wiring harness needs to have a certain degree of flexibility to facilitate installation and wiring in the complex layout inside the household appliances.

4. High temperature and chemical corrosion resistance: Some household appliances such as ovens and microwave ovens will generate high temperatures when working, and the wiring harness needs to be able to withstand high temperature environments. In addition, the wiring harness material also needs to resist possible chemical corrosion.

Common materials

- Wire: Copper wire is usually used because of its good conductivity.

- Insulation materials: such as PVC (polyvinyl chloride), XLPE (cross-linked polyethylene), etc., are used to protect the wires and prevent short circuits.

- Jacket materials: used to protect the entire wiring harness, common ones are PVC, TPE (thermoplastic elastomer), etc.

Manufacturing process

1. Cutting: Cut the wires according to the design requirements.

2. Stripping: Remove the insulation layer at the end of the wire to connect the terminal.

3. Crimping: Crimping the terminal to the wire to ensure a good electrical connection.

4. Assembly: Assemble multiple wires into a harness according to the design requirements and fix them with tape or sleeves.

5. Testing: Electrically test the finished harness to ensure that it meets the design requirements and safety standards.

Application examples

- Washing machine: Connect motors, control panels, sensors, etc.

- Refrigerator: Connect compressors, thermostats, lighting, etc.

- Air conditioner: Connect compressors, fans, control panels, etc.

Notes

- Installation: When installing the wiring harness, avoid excessive bending or stretching to prevent wire breakage or insulation damage.

- Maintenance: Check the wiring harness regularly to ensure that it is not aged, damaged or loose.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

How does the Household Appliances Wiring Harness of Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. perform in a high humidity environment?

In the daily operation of household appliances, high humidity environments—such as the steamy atmosphere inside a washing machine during a cycle, the moist interior of a refrigerator’s fresh-keeping compartment, or the humid corners where small kitchen appliances reside—pose a hidden threat to their internal components. Among these, the wiring harness, as the "nerve center" connecting all electronic parts, bears the brunt of moisture-related challenges. For Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd., a 20-year veteran in the field, its household appliances wiring harnesses have been engineered to excel in such demanding conditions, backed by robust expertise, advanced infrastructure, and a relentless focus on quality.

The Critical Role of Wiring Harnesses in High Humidity: Why It Matters

Household appliances wiring harnesses are the unsung heroes that enable power transmission and signal control between components—from a washing machine’s motor to a refrigerator’s thermostat. In high humidity, moisture can seep into insulation layers, corrode conductors, or cause short circuits, compromising safety and functionality. This is where the performance of a wiring harness becomes make-or-break: it must resist moisture penetration, prevent conductor oxidation, and maintain stable electrical conductivity, even after years of exposure.

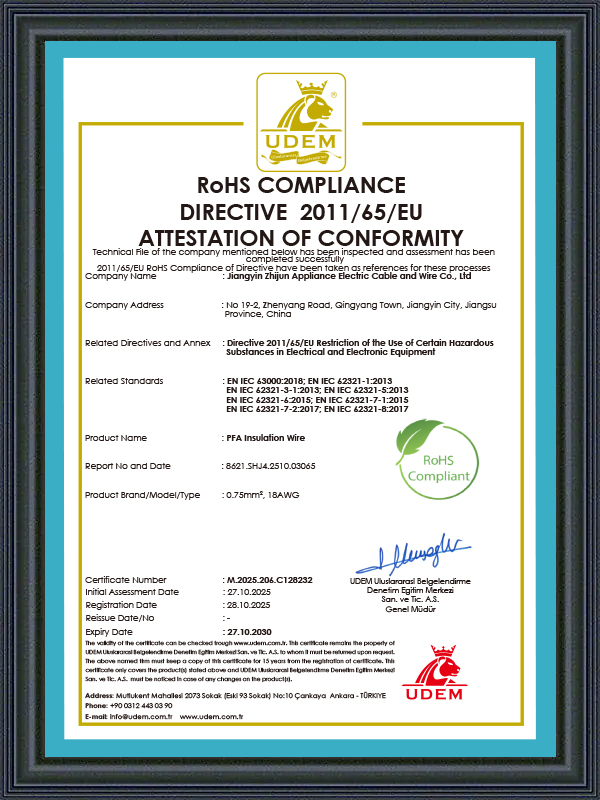

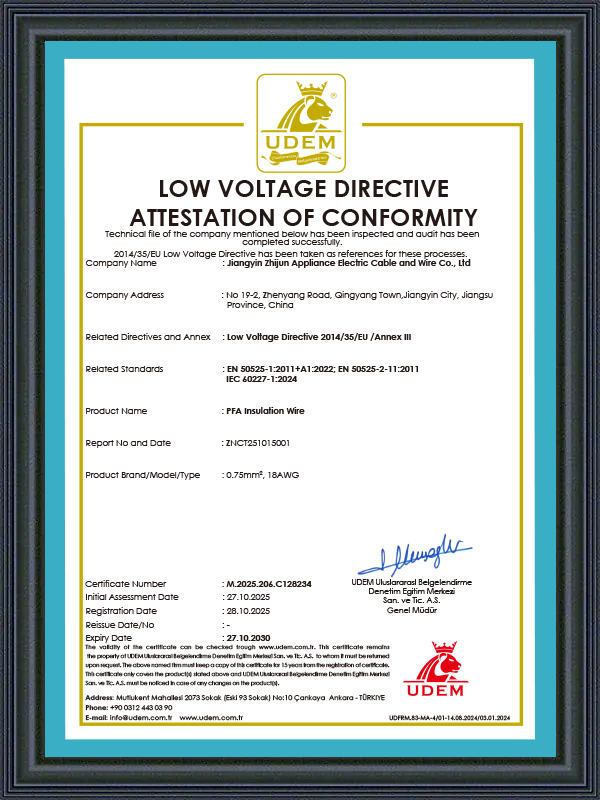

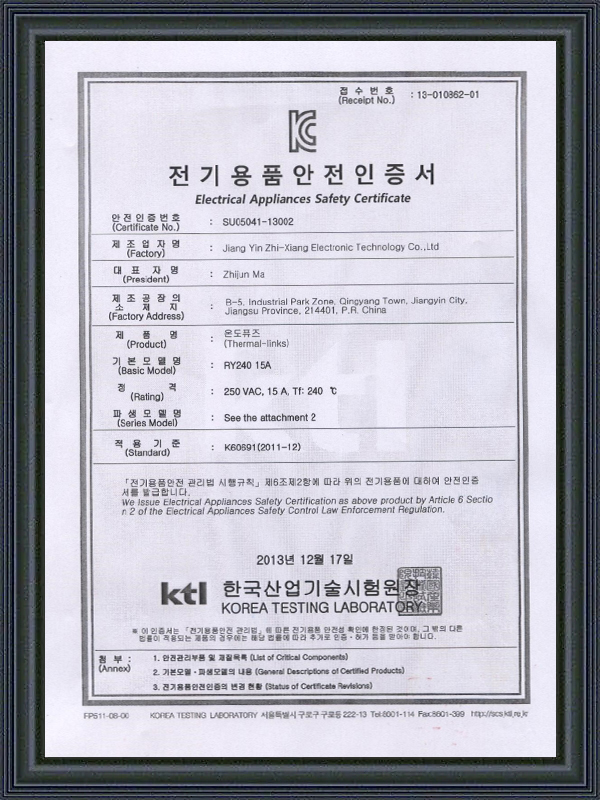

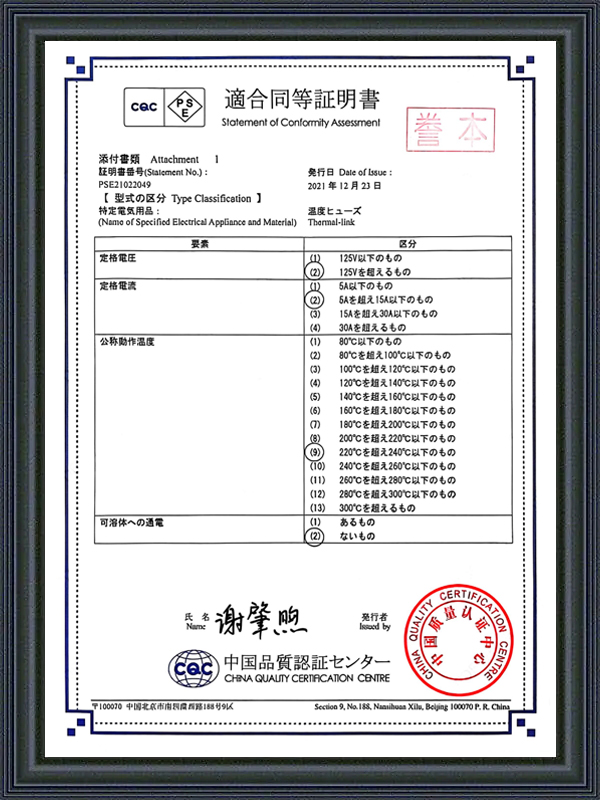

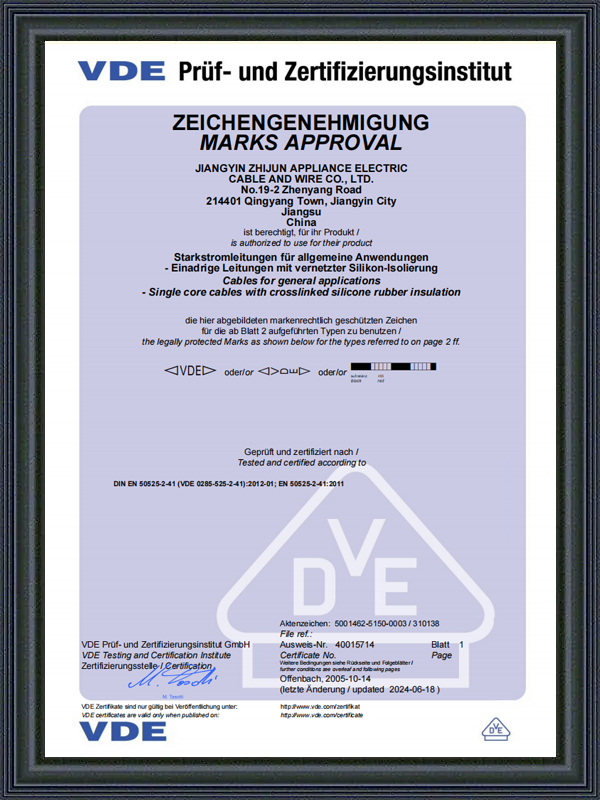

Zhijun’s Edge: 20 Years of Expertise in High-Performance Materials & Manufacturing

Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. stands out in addressing these challenges, thanks to its deep-rooted specialization. With a 20,000-square-meter factory, over 200 employees, and a 30-strong technical team, the company has honed its craft in developing and producing high-temperature resistant wires (silicone rubber, PVC, radiation crosslinking, Teflon series) and small home appliance wiring harnesses. Its advanced production management equipment, precision testing instruments, and rigorous quality assurance system—complete with full traceability—ensure every harness is built to withstand harsh environments, including high humidity.

Material Science: The Foundation of Moisture Resistance

The secret to Zhijun’s humidity-resistant harnesses lies in its meticulous material selection:

Conductors: High-purity copper wires, known for excellent conductivity, are treated to resist oxidation. Even in humid conditions, they maintain low resistance and stable performance, avoiding corrosion that could disrupt power or signal transmission.

Insulation & Jacket Materials: PVC, XLPE, TPE, and Teflon are chosen not just for high-temperature resistance but also for their impermeability to moisture. PVC and TPE jackets form a tight seal around the harness, blocking moisture from reaching internal wires. Teflon, with its chemical inertness, adds an extra layer of protection in environments where humidity is paired with mild detergents (e.g., washing machines).

Specialized Coatings: For extreme humidity scenarios, select harnesses feature moisture-resistant coatings on insulation layers, further repelling water and preventing mold growth.

Manufacturing Precision: Ensuring Seamless, Moisture-Proof Construction

Zhijun’s manufacturing process leaves no room for compromise, directly enhancing humidity resistance:

Stripping & Crimping: Precision stripping ensures minimal exposure of conductors, while tight crimping of terminals creates a moisture-tight seal, preventing water ingress at connection points.

Assembly & Sealing: Multiple wires are bundled and sealed with moisture-resistant tape or sleeves, eliminating gaps where moisture could accumulate. This tight bundling also reduces the surface area exposed to humidity.

Rigorous Testing: Every harness undergoes stringent electrical and environmental tests, including humidity chamber simulations. These tests replicate years of high-humidity exposure, ensuring the harness maintains insulation integrity and conductivity.

Real-World Performance: Applications in Humidity-Prone Appliances

Zhijun’s harnesses prove their mettle in appliances where humidity is a constant:

Washing Machines: Connecting motors, control panels, and sensors, these harnesses endure repeated cycles of steam and water splashes. Their moisture-resistant jackets and sealed terminals prevent short circuits, even in the dampest corners of the appliance.

Refrigerators: Inside cold, humid compartments (e.g., vegetable crispers), the harnesses resist condensation buildup. Their insulation remains flexible and intact, ensuring reliable connections between compressors, thermostats, and lighting.

Small Kitchen Appliances: Blenders, food processors, and coffee makers—often used near sinks—benefit from Zhijun’s harnesses, which withstand occasional water splatters without degradation.

Quality Assurance: Backed by Systems You Can Trust

Zhijun’s rigorous quality assurance and traceability systems ensure consistency. Every harness is tracked from raw material to delivery, with records of material 批次,production parameters, and test results. This means if a humidity-related issue ever arises (a rarity), the root cause can be swiftly identified and resolved—though the company’s 20-year track record speaks to its reliability.

In high humidity, household appliances demand wiring harnesses that are more than just conductors—they are guardians of safety and performance. Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd., with its expertise in materials, precision manufacturing, and unwavering commitment to quality, delivers harnesses that thrive in moisture-rich conditions. Whether in a steamy washing machine or a humid refrigerator, Zhijun’s products ensure long-lasting, safe, and stable operation—proving that when it comes to humidity resistance, experience and precision make all the difference.

English

English عربى

عربى Español

Español