Irradiation cross-linking UL3713 is a wire and cable material standard, which is usually used in electronic wires, automotive wires, home appliance wires and ot...

Irradiated Cross-Linked Wire Suppliers

-

-

UL1430 Irradiation Cross-Linked Xlpvc Connecting Wire

UL1430 Irradiation Cross-Linked Xlpvc Connecting WireUpgrade your electrical systems with our UL1430 Irradiation cross-linked XLPVC connecting wire, designed for reliability in high-performance applications. Rated...

-

UL1431 105°C Easy-to-cut Wire Irradiation Cross-linked Connection Wire

UL1431 105°C Easy-to-cut Wire Irradiation Cross-linked Connection WireIntroducing the UL1431 105°C Easy-to-cut Irradiation Cross-linked Connection Wire – a cutting-edge solution engineered for internal wiring in various electronic...

-

UL3266 300v Electrical Equipment Connection Wire Xlpe Insulation

UL3266 300v Electrical Equipment Connection Wire Xlpe InsulationWith a rated voltage of 300V and a robust operating temperature of up to 125°C, this UL3266 300V electrical equipment connection wire XLPE insulation is designe...

-

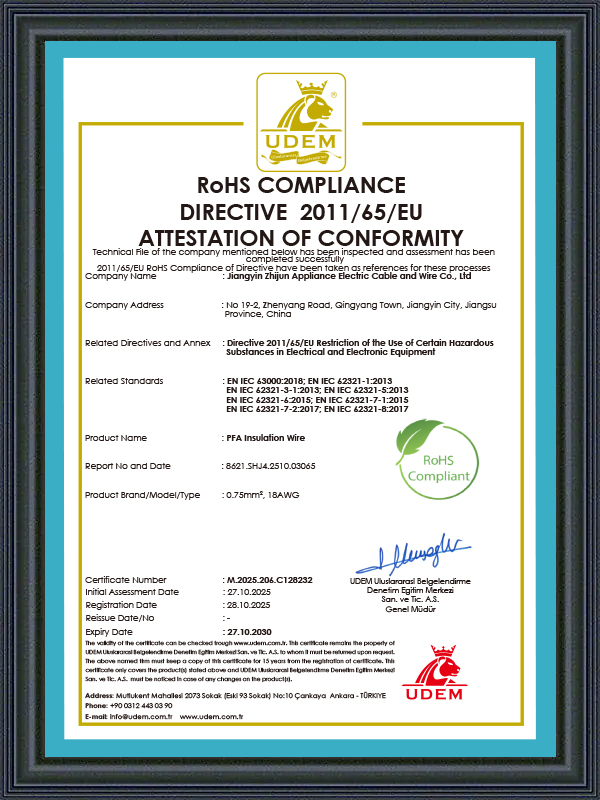

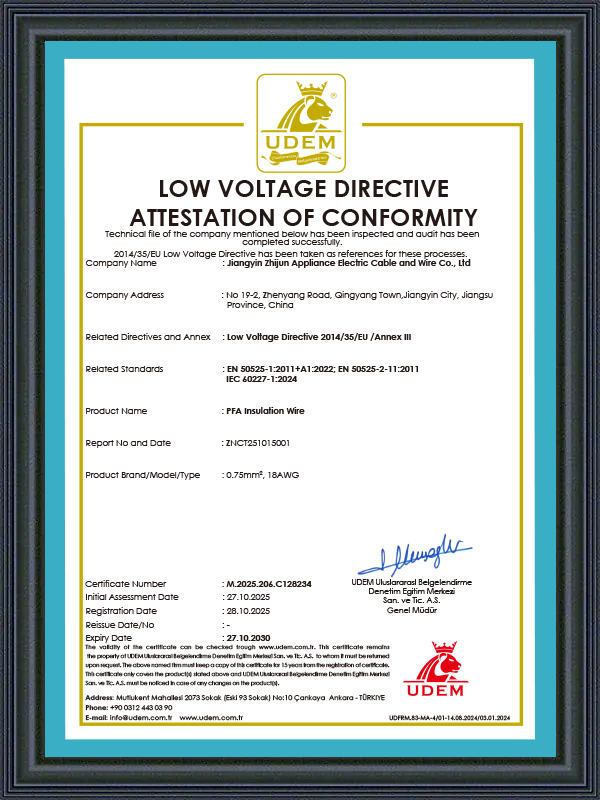

UL3271 600v Environmentally Friendly Rohs Flame Retardant Irradiated Wire

UL3271 600v Environmentally Friendly Rohs Flame Retardant Irradiated WireThe UL3271 600V environmentally friendly Rohs flame retardant irradiated wire is a premium electrical solution designed to meet the demands of modern industries...

-

UL3321 150°C Irradiation Cross-Linked Flame Retardant Connecting Wire

UL3321 150°C Irradiation Cross-Linked Flame Retardant Connecting WireEngineered for extreme environments, UL3321 combines superior safety and convenience in one robust package. Rated for 150°C operating temperatures and 600V volt...

-

UL3398 Xlpe Insulation Rohs Compliant Tinned Copper Wire Connecting Conductor

UL3398 Xlpe Insulation Rohs Compliant Tinned Copper Wire Connecting ConductorIntroducing the UL3398 XLPE Insulation Tinned Copper Wire Connecting Conductor – a cutting-edge solution for modern electronic and electrical systems. Engineere...

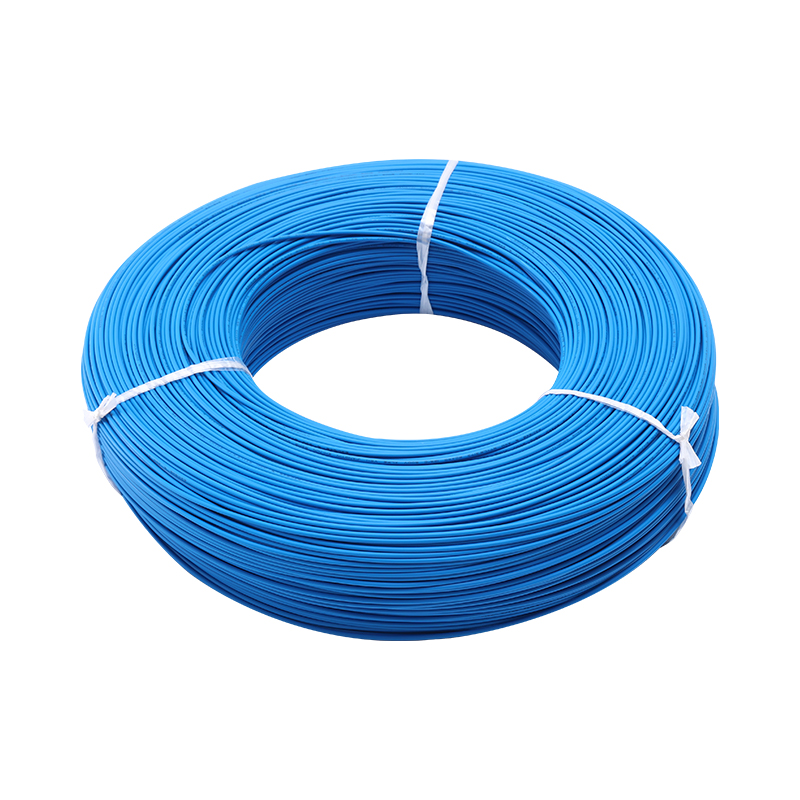

Irradiation cross-linked wire is a wire that uses irradiation technology to make the wire insulation material undergo a cross-linking reaction, thereby improving its performance. The following is a detailed introduction to irradiation cross-linked wire:

Definition

Irradiation cross-linked wire uses high-energy rays (such as electron beams or gamma rays) to irradiate the wire insulation layer, causing its molecular structure to cross-link and form a three-dimensional network structure, thereby enhancing the performance of the insulation material.

2. Manufacturing process

- Material selection: Commonly used insulating materials include polyethylene (PE), polyvinyl chloride (PVC), etc.

- Irradiation treatment: Irradiate the insulation layer through an electron accelerator or a gamma ray source to induce a cross-linking reaction.

- Cooling and post-treatment: Cool after irradiation and perform necessary post-treatment to ensure stable performance.

3. Advantages

- Heat resistance: After cross-linking, the heat resistance is significantly improved and can work at higher temperatures.

- Mechanical strength: Enhanced mechanical properties, improved tensile strength and wear resistance.

- Electrical properties: Better insulation resistance and withstand voltage performance.

- Chemical stability: Enhanced chemical corrosion resistance and extended service life.

4. Application areas

- Power transmission: used for high-voltage and ultra-high-voltage transmission lines.

- Aerospace: suitable for high-temperature and high-radiation environments.

- Automotive industry: used for high-temperature parts such as engine compartments.

- Household appliances: used for high-temperature appliances such as electric water heaters and microwave ovens.

5. Future development

- New material research and development: development of more efficient insulation materials.

- Process optimization: improve irradiation efficiency and reduce costs.

- Environmental protection: research on more environmentally friendly irradiation technologies and materials.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

How Irradiated Cross-Linked Wire Improves Motor Wiring Performance?

In the world of electrical systems, particularly in motors, the quality of the wiring used can significantly impact the overall performance, durability, and safety of the device. A key innovation that has transformed the performance of motor wiring is irradiated cross-linked wire. This specialized type of wiring, with its enhanced properties, offers significant benefits over traditional wiring materials.

What is Irradiated Cross-Linked Wire?

Irradiated cross-linked wire is a type of wire whose insulation undergoes a unique process called irradiation crosslinking. In this process, the wire's insulating material—often made from polymers like polyethylene or PVC—is exposed to high doses of radiation. This radiation causes the molecular chains of the polymer to bond in a way that creates a three-dimensional network structure, or “cross-links,” which results in improved material properties.

This process gives the wire several advantages, including increased heat resistance, better electrical insulation, and enhanced mechanical strength, all of which are crucial for the performance of electrical motors. The characteristics of irradiated cross-linked wire make it ideal for applications where wires are exposed to challenging environmental factors like high temperatures, vibrations, and moisture.

Enhancing Heat Resistance in Motor Wiring

One of the most significant improvements offered by irradiation crosslinking motor wiring is its heat resistance. In motors, especially those operating in high-demand environments such as industrial machines, heating elements, and automotive applications, wires are often subjected to elevated temperatures. Traditional wires may suffer from insulation degradation, which can lead to short circuits, reduced performance, or even complete motor failure.

Irradiated cross-linked wires, due to their improved thermal stability, can withstand much higher temperatures than conventional wires. This is critical in motor wiring, as it ensures the longevity of the wires even when motors are subjected to prolonged heating or high power outputs. As a result, motors can perform at higher efficiencies and continue to operate reliably without the risk of overheating and insulation breakdown.

Improved Mechanical Strength and Durability

In addition to heat resistance, irradiated cross-linked wire also offers superior mechanical strength. Motors often operate under dynamic conditions where wires are subject to constant vibrations, flexing, and even mechanical abrasion. Over time, these stresses can cause the wires’ insulation to crack or break down, leading to electrical faults and motor failure.

The cross-linking process strengthens the wire's insulation, making it much more durable and resistant to mechanical damage. This enhanced abrasion resistance ensures that the wiring remains intact even in challenging environments, significantly reducing the likelihood of failure due to physical wear and tear. This is particularly important in motors used in heavy-duty industrial equipment or vehicles, where vibration and movement are constant.

Superior Electrical Insulation for Motor Wiring

Electrical motors rely on highly effective insulation to prevent short circuits and electrical leakage, which can not only impair performance but also create dangerous conditions. The cross-linked structure of irradiated wire provides superior electrical insulation. The three-dimensional network of the polymer insulation resists degradation and retains its insulating properties even in harsh conditions, such as high temperatures, moisture, and exposure to chemicals.

This enhanced insulation capability means that irradiated cross-linked wires maintain their electrical integrity over time, ensuring that the motor operates safely and efficiently. This is particularly important for motors used in appliances, industrial machinery, and automotive systems, where reliable insulation is essential to prevent electrical faults and ensure continuous, trouble-free operation.

Resistance to Environmental Factors

The irradiation cross-linking process also imparts additional resistance to environmental factors such as moisture, chemicals, and UV radiation. In many motor applications, wiring is exposed to outdoor conditions or harsh industrial environments where exposure to water, oils, solvents, and UV light is common. Over time, these environmental factors can weaken the insulation of traditional wiring materials, leading to reduced performance and potential failures.

However, irradiated cross-linked wire offers exceptional resistance to these environmental stressors. Its moisture resistance prevents degradation caused by water exposure, while its chemical resistance ensures that it performs well even when exposed to oils, acids, and solvents. UV resistance is also a key feature, allowing the wiring to remain functional when exposed to sunlight or other sources of ultraviolet radiation. This makes it an ideal solution for outdoor motors or motors used in harsh industrial environments.

Reduced Risk of Electrical Failures and Downtime

The enhanced properties of irradiated cross-linked wire directly contribute to the reliability of motor systems. With improved heat resistance, mechanical strength, electrical insulation, and environmental durability, the risk of electrical failures is significantly reduced. This translates to fewer maintenance needs, less downtime, and longer service life for the motors.

In industries where uptime is crucial—such as automotive manufacturing, energy production, and even household appliances—the reliability of motor wiring is a critical factor. By choosing irradiated cross-linked wire for motor wiring, manufacturers can ensure that their motors continue to perform optimally without the frequent need for costly repairs or replacements.

Applications in Motor Wiring

The benefits of irradiated cross-linked wire have made it an essential component in a wide range of motor applications. Whether in small household appliances or large industrial motors, the wire’s durability and enhanced performance make it a preferred choice for many manufacturers.

Household appliances: In appliances like washing machines, refrigerators, and air conditioners, motors play a key role, and the wiring must be able to withstand the rigors of daily use. Irradiated cross-linked wires ensure that the motors continue to operate efficiently, even under challenging conditions like high humidity or heat.

Automotive applications: Motors in vehicles, from electric vehicles to traditional internal combustion engines, require highly durable and heat-resistant wiring. Irradiated cross-linked wires provide the needed insulation and resistance to temperature fluctuations and environmental exposure, ensuring the motors function smoothly.

Industrial motors: Motors used in heavy-duty equipment, such as pumps, compressors, and manufacturing machinery, often face extreme conditions. The enhanced properties of irradiated cross-linked wire ensure that the motor wiring remains intact and functional, even in demanding environments.

Why Choose Irradiated Cross-Linked Wire?

The decision to use irradiated cross-linked wire in motor systems offers manufacturers several advantages. Not only does it improve the overall performance of the motor, but it also helps to extend the lifespan of the device and reduce the frequency of failures. This makes it a cost-effective solution in the long term, as it minimizes downtime and the need for repairs or replacements.

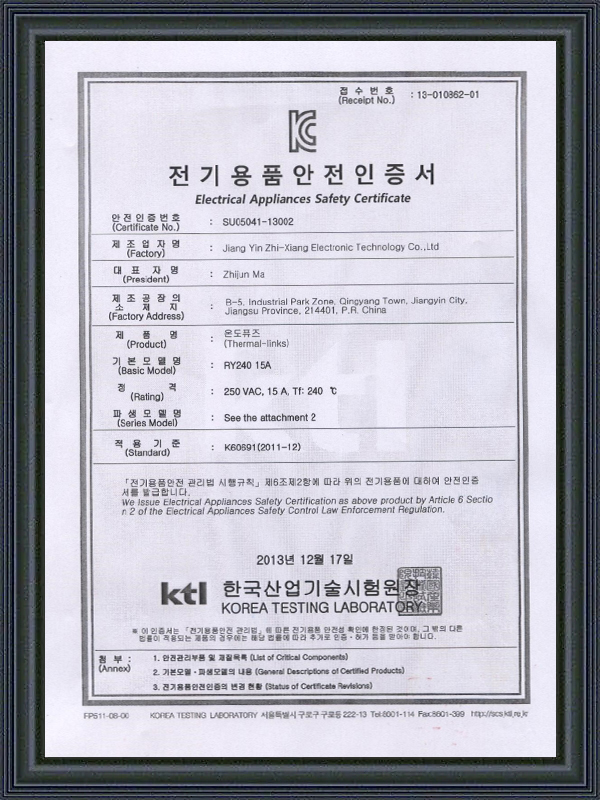

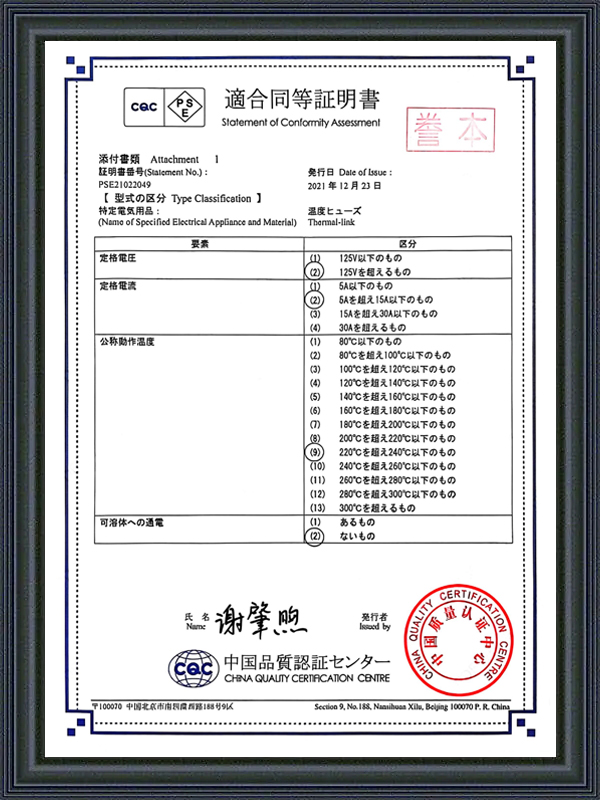

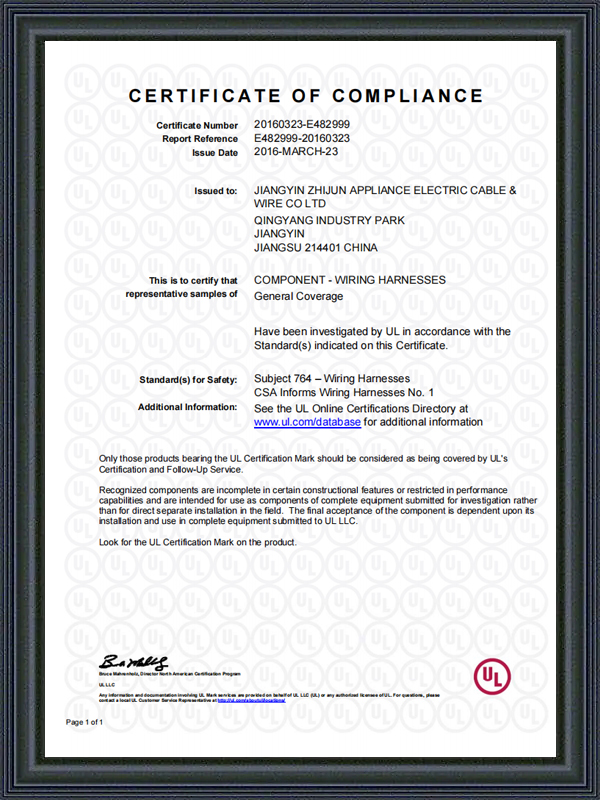

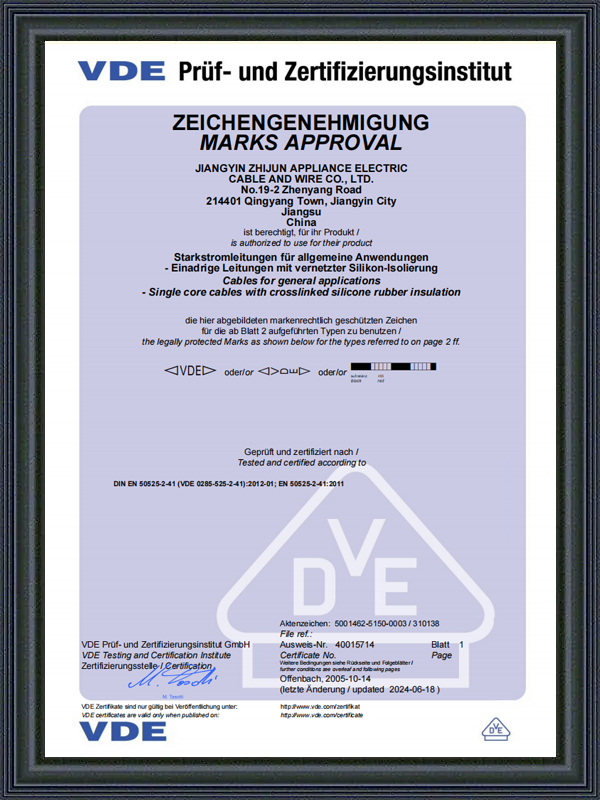

At Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd., we specialize in the development and production of high-quality irradiation cross-linking motor wiring. With over 20 years of experience and a focus on innovation, we provide products that meet the highest safety and performance standards. Our advanced manufacturing techniques and quality control processes ensure that our wiring solutions are reliable, durable, and designed to enhance the performance of motors in a wide range of applications.

Irradiated cross-linked wire is a game-changer in the field of motor wiring, offering significant improvements in heat resistance, mechanical strength, electrical insulation, and resistance to environmental factors. By incorporating this advanced wire into motor systems, manufacturers can ensure the longevity, reliability, and efficiency of their products, all while reducing the risk of electrical failures and costly downtime. As technology continues to advance, the role of irradiated cross-linked wire in improving motor wiring performance will only become more crucial, making it a key component in the future of motor-driven systems.

English

English عربى

عربى Español

Español