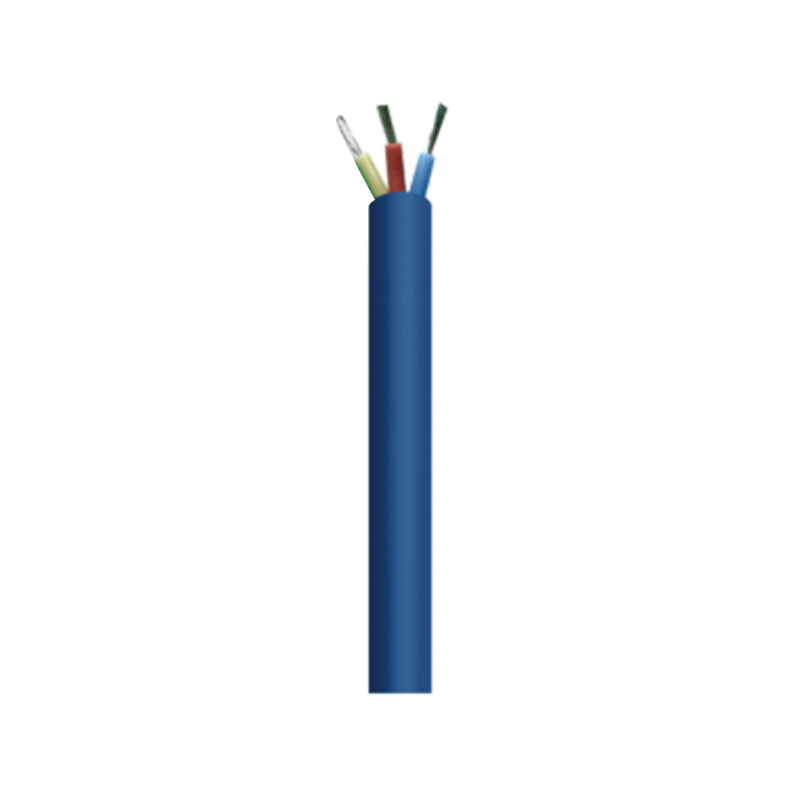

Designed with a dual-layer PVC construction, this 60227IEC52 RVV 3C certified PVC sheathed flexible wire for connection features an insulation layer crafted fro...

Vehicle Power Cable Factory

-

-

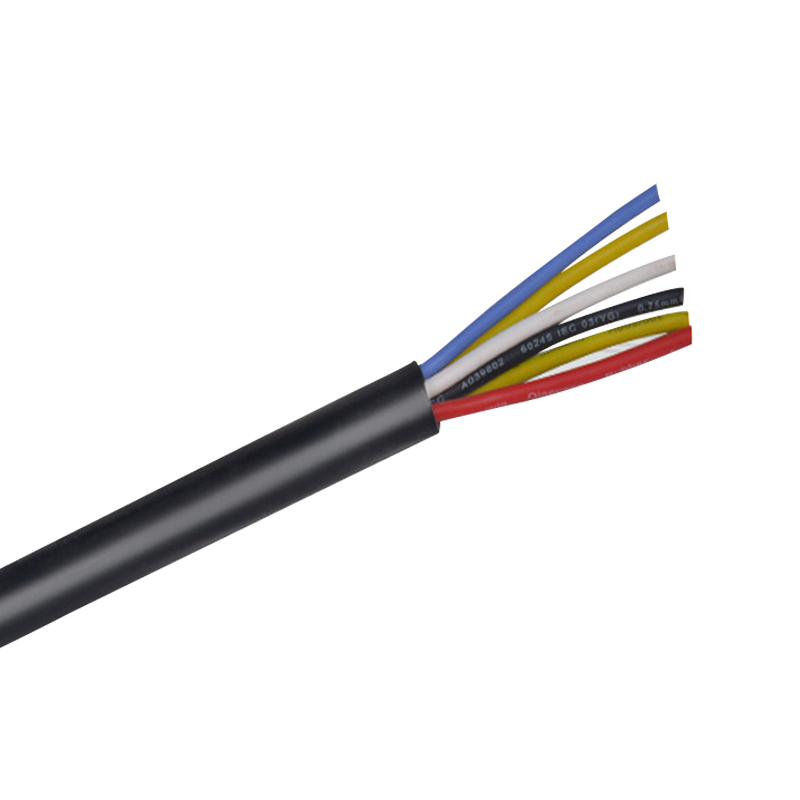

60227IEC53 RVV National Standard Certified Pvc Installation Sheathed Wire

60227IEC53 RVV National Standard Certified Pvc Installation Sheathed WireThe 60227IEC53 RVV national standard certified PVC installation sheathed wire, certified to national standards, combines exceptional flexibility with rugged dur...

-

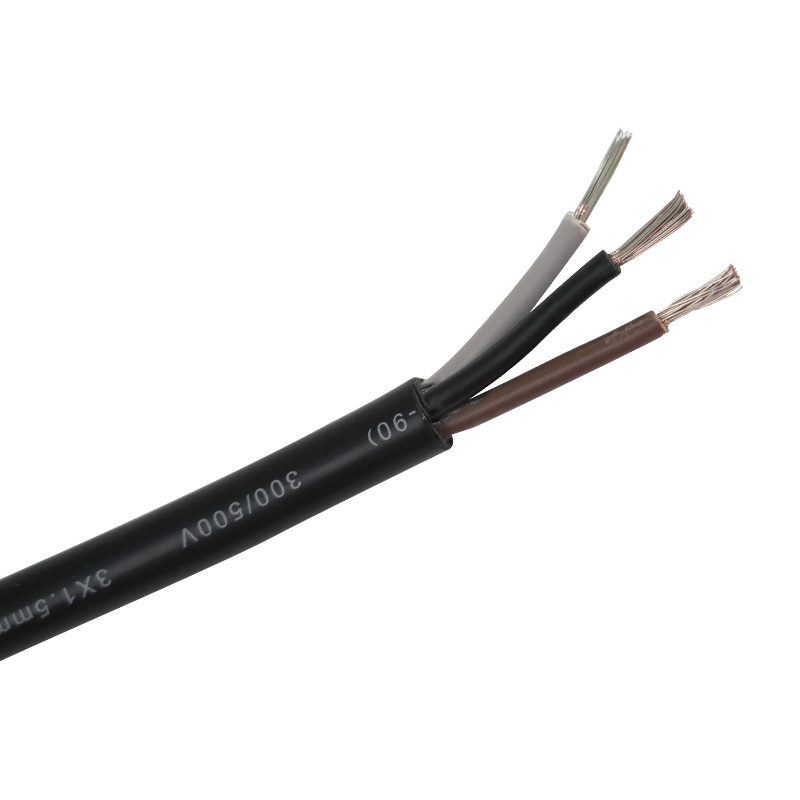

60227IEC56 RVV-90 90°C National Standard Pvc Flexible Cable 300v

60227IEC56 RVV-90 90°C National Standard Pvc Flexible Cable 300vThis 60227IEC56 RVV-90 90°C national standard PVC flexible cable 300V is engineered to operate at temperatures up to 90°C and is rated for both 300V and 500V sy...

-

60227IEC57 RVV-90 300/500V Sheathed Pvc Flexible Cable

60227IEC57 RVV-90 300/500V Sheathed Pvc Flexible CableRVV cable is a common PVC insulated PVC sheathed soft cable, which is widely used in electrical appliances, instruments and electronic equipment. The following ...

-

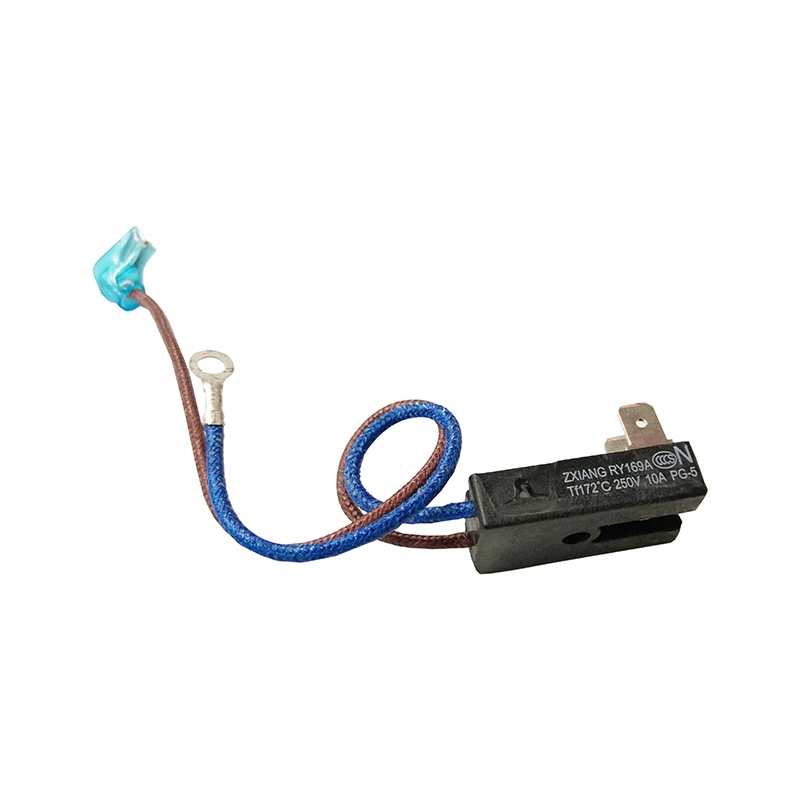

Thermal Fuse Assembly Potting Components For Thermal Fuses Inside Home Appliances

Thermal Fuse Assembly Potting Components For Thermal Fuses Inside Home AppliancesThermal cut-off potting components are a device used for circuit protection, usually used to prevent circuit damage due to overheating. It protects the device b...

-

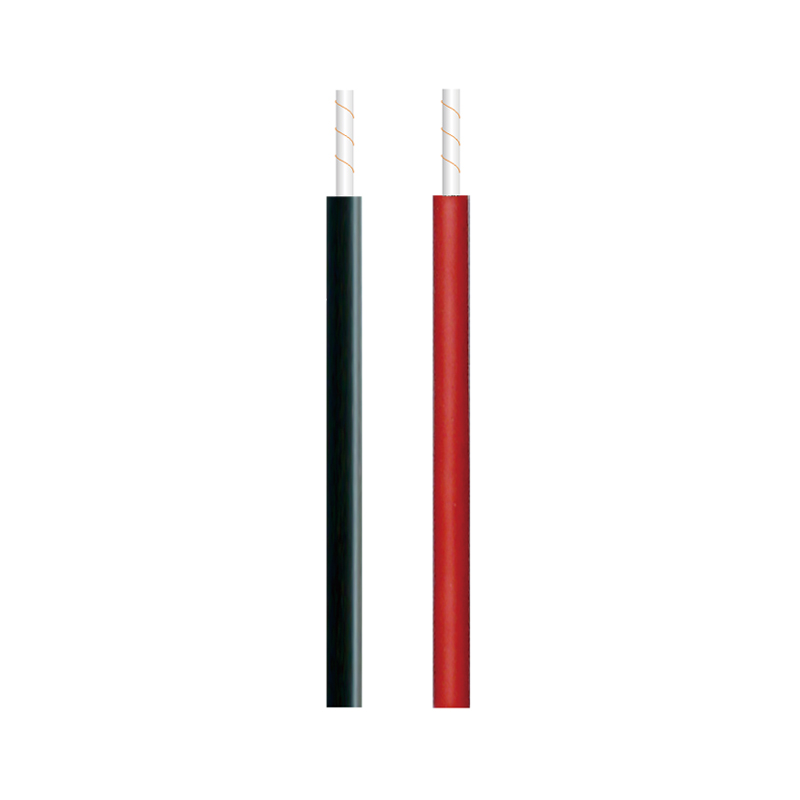

Silicone Rubber Electric Heating Wire

Silicone Rubber Electric Heating WireHeating wire: nickel-chromium alloy wire wrapped with glass fiber yarnInsulator: silicone rubber (double-layer silicone insulation can be customized)Silicone ru...

-

Automotive internal high voltage cable EV/EVP

Automotive internal high voltage cable EV/EVPRated temperature: -40°C~150°CRated voltage: 1500VConductor: bare copperInsulation: 125°C, 150°C thermosetting elastomerBending radius: ≥5xODThe EV/EVP high-vol...

-

AVX/AEX Japanese Automotive Wire

AVX/AEX Japanese Automotive Wire·Rated Temperature: 100℃/120℃·Conductor: Stranded 0.5~8mm² bare copper·Insulation: XLPVC/XLPE insulation, RoHS compliant·Passes flame retardant test, uses stand...

-

QVR/QVR-105 National Standard Automotive Wire

QVR/QVR-105 National Standard Automotive Wire·Rated Temperature: 70℃/105℃·Conductor: Stranded 0.2~120mm² tin-plated or bare copper·Insulation: PVC insulation, RoHS compliant·Passes flame retardant test, us...

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

The key role of vehicle power cable in the power transmission system of new energy vehicles

As the global automotive industry continues its shift towards electrification, the importance of high-performance vehicle power cables in new energy vehicles (NEVs) has never been greater. These specialized cables serve as the central nervous system of the vehicle, enabling efficient, stable, and safe power transmission between core components such as batteries, inverters, electric motors, and control units. Among the leading manufacturers in this domain, Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. has emerged as a trusted name by delivering advanced cable solutions for the evolving needs of the NEV industry.

Understanding the Role of Power Cables in NEVs

Unlike traditional internal combustion engine (ICE) vehicles, NEVs rely entirely on electrical energy for propulsion. This shift demands high-voltage, high-temperature-resistant power cables that can handle the increased load and complexity of modern electric drivetrains. Vehicle power cables must ensure uninterrupted current flow, withstand harsh environmental conditions, and comply with strict safety standards to avoid breakdowns or failures.

These cables not only connect the battery pack to the electric motor but also support auxiliary systems such as onboard chargers, regenerative braking, and thermal management units. Therefore, any weakness in the cable infrastructure could significantly impact vehicle performance, safety, and lifespan.

Jiangyin Zhijun: Excellence Through Experience and Innovation

Established with nearly 20 years of focused expertise in high-temperature-resistant wire and wiring harness assembly, Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. brings significant industry knowledge and technical competence to the NEV sector. With a modern manufacturing facility covering nearly 20,000 square meters and a workforce of over 200 employees, including a technical team of 30 professionals, the company is equipped with advanced production management systems, precision testing instruments, and a rigorous quality assurance and traceability system.

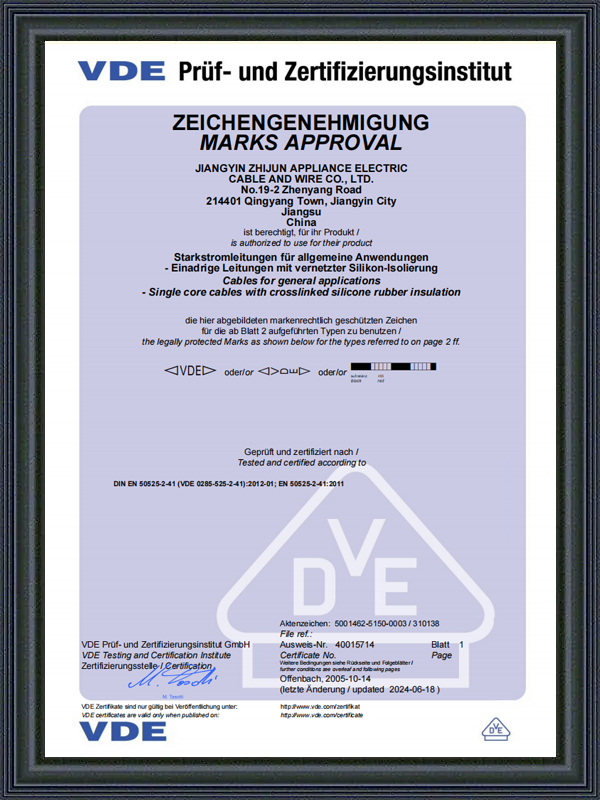

Zhijun specializes in a range of high-performance wire types including silicone rubber series, PVC series, radiation crosslinking series, and Teflon series, all of which are ideal for the demanding conditions found in NEVs. These wires offer excellent thermal stability, electrical insulation, chemical resistance, and mechanical durability — qualities that are essential for electric vehicle applications.

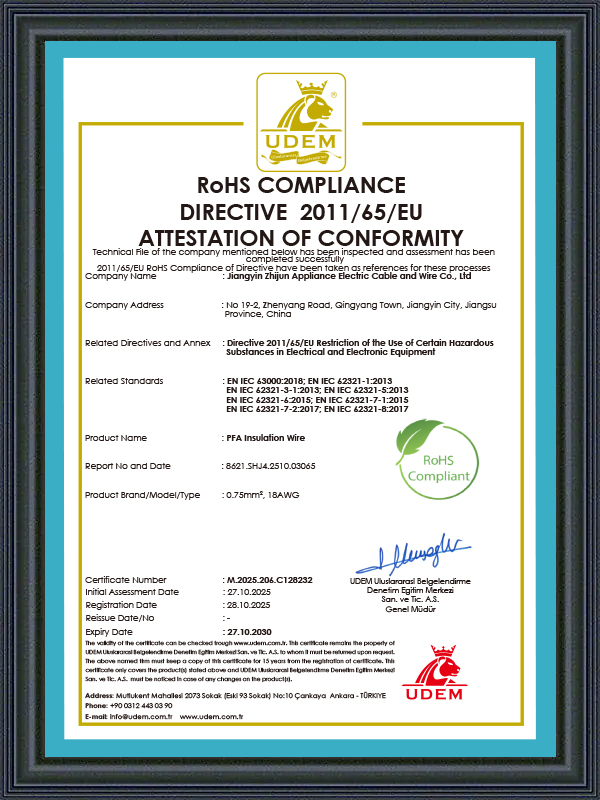

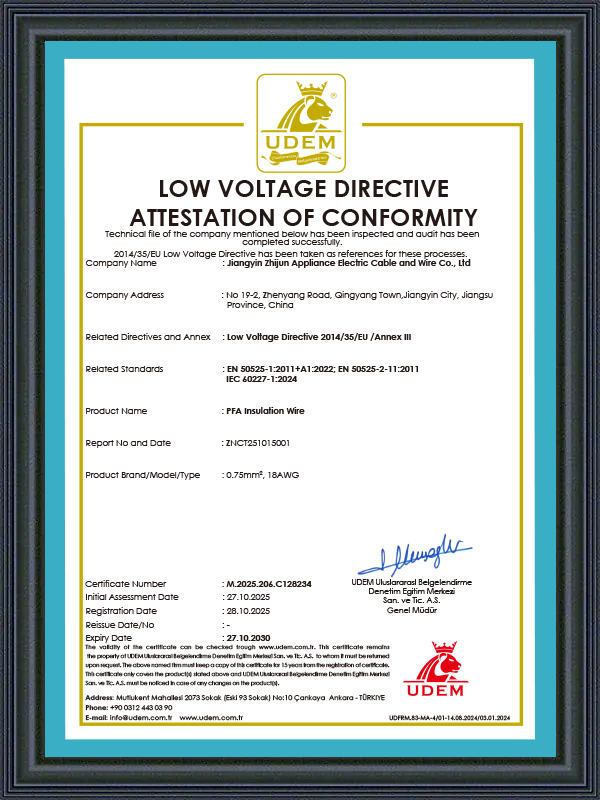

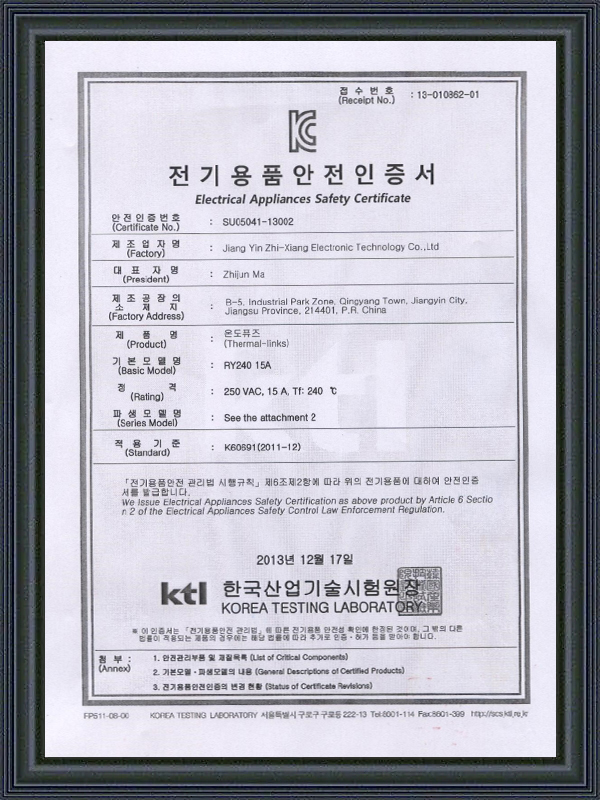

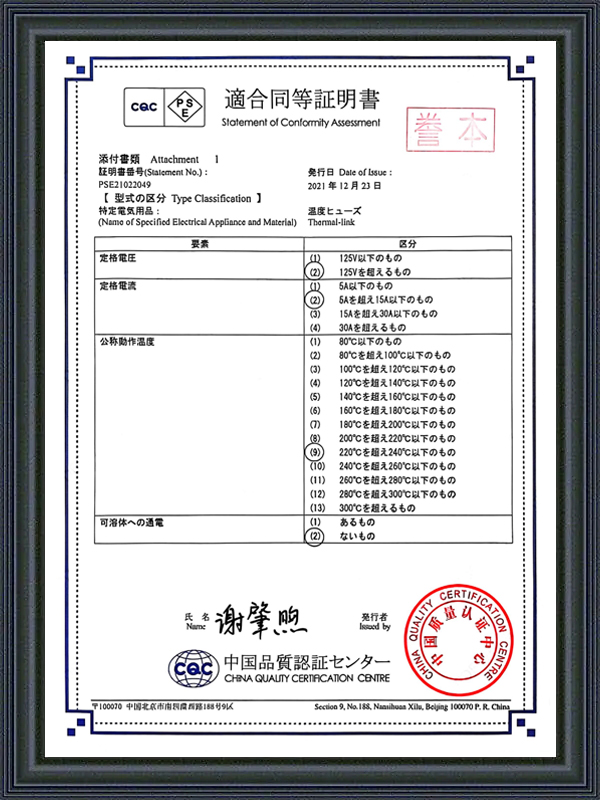

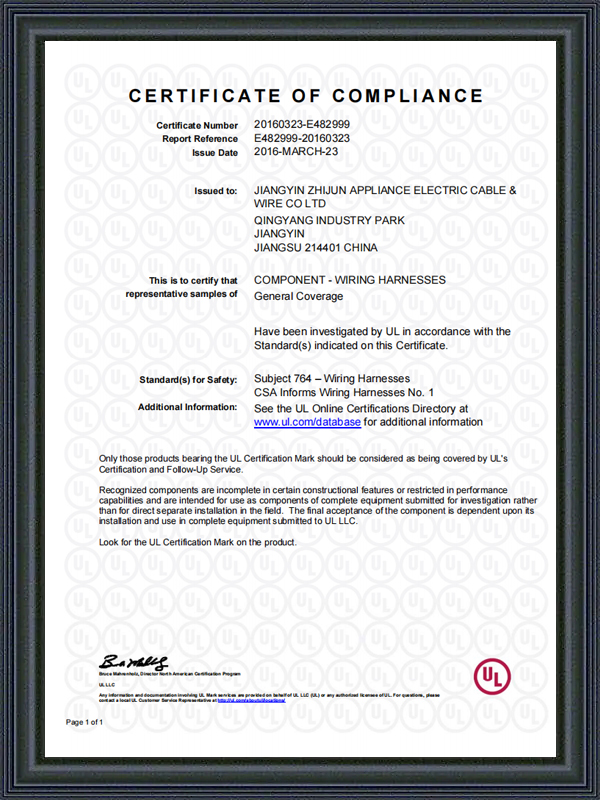

Commitment to Quality and Certification

Zhijun’s commitment to quality is evident in the comprehensive certification of its products. All offerings comply with international safety and environmental standards such as UL, VDE, TUV, CCC, KC, PSE, ROHS, and REACH. The company itself is certified with ISO9001:2015 international quality management system, ensuring that every product adheres to the highest benchmarks of reliability and safety.

This dedication has earned Jiangyin Zhijun recognition as a designated supplier for leading global brands including Midea, Gree, TCL, Hisense, Supor, Jiuyang, Tsinghua Tongfang, and many more. The company has positioned itself as an innovative and influential supporting partner in the home appliance and automotive wire industry, with its products now making inroads into the growing electric mobility market.

Meeting the Demands of New Energy Vehicles

NEVs place unique demands on cable performance. Power cables must handle voltages ranging from 400V to over 800V in some models, while also enduring mechanical vibration, extreme temperature fluctuations, humidity, oil exposure, and electromagnetic interference. Zhijun’s radiation crosslinking and Teflon series wires are specifically engineered to address these challenges, offering high dielectric strength, flame resistance, and long-term thermal stability up to 200°C or more.

Additionally, Zhijun’s experience in small home appliance internal wiring and molding gives it an edge in precision engineering and customization — two factors increasingly sought after by NEV manufacturers. Whether it is cable assembly, connector integration, or specialized insulation structures, the company offers tailor-made solutions that meet the stringent design and safety standards of electric vehicles.

Driving Sustainable Mobility Forward

With the global push toward carbon neutrality, vehicle electrification will continue to gain momentum. As a crucial component of electric vehicle architecture, UL certified wire play a pivotal role in enabling efficient power distribution, safety, and overall system reliability. Jiangyin Zhijun is well-positioned to support this transition through its cutting-edge products, robust manufacturing capabilities, and customer-centric approach.

By continually investing in R&D and production innovation, Jiangyin Zhijun aims to "create value for customers" and become a leading provider of high-performance cable solutions for the future of transportation. Its expansion into the NEV market reflects both strategic foresight and technical readiness to meet the dynamic challenges of green mobility.

As NEVs reshape the automotive landscape, the demand for high-quality vehicle power cables will continue to grow. Jiangyin Zhijun Appliance Electric Cable and Wire Co., Ltd. stands out as a reliable and forward-thinking partner, offering proven solutions that ensure safety, performance, and sustainability in tomorrow’s electric vehicles.

English

English عربى

عربى Español

Español