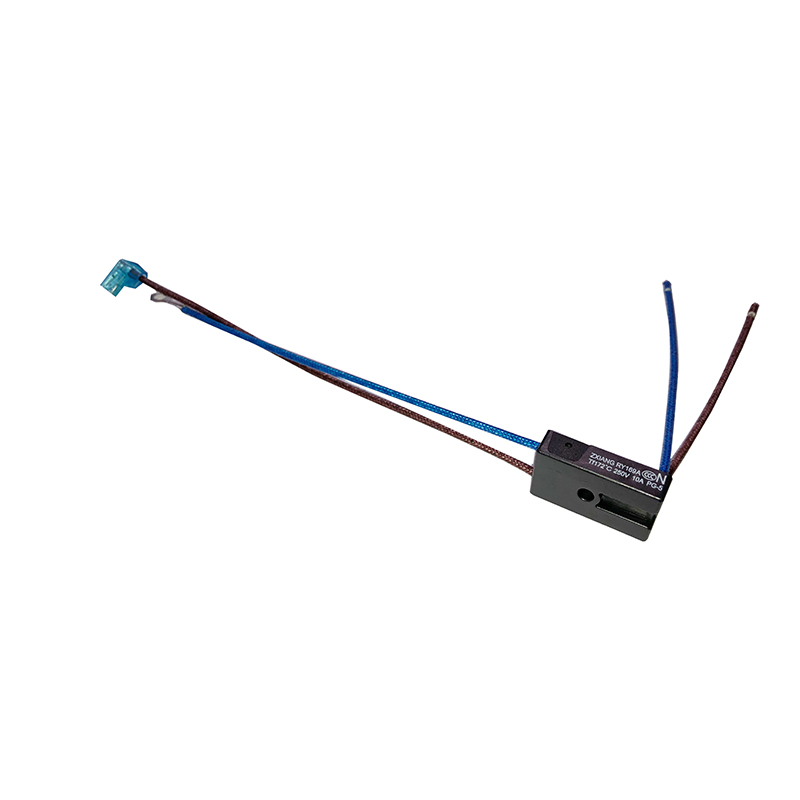

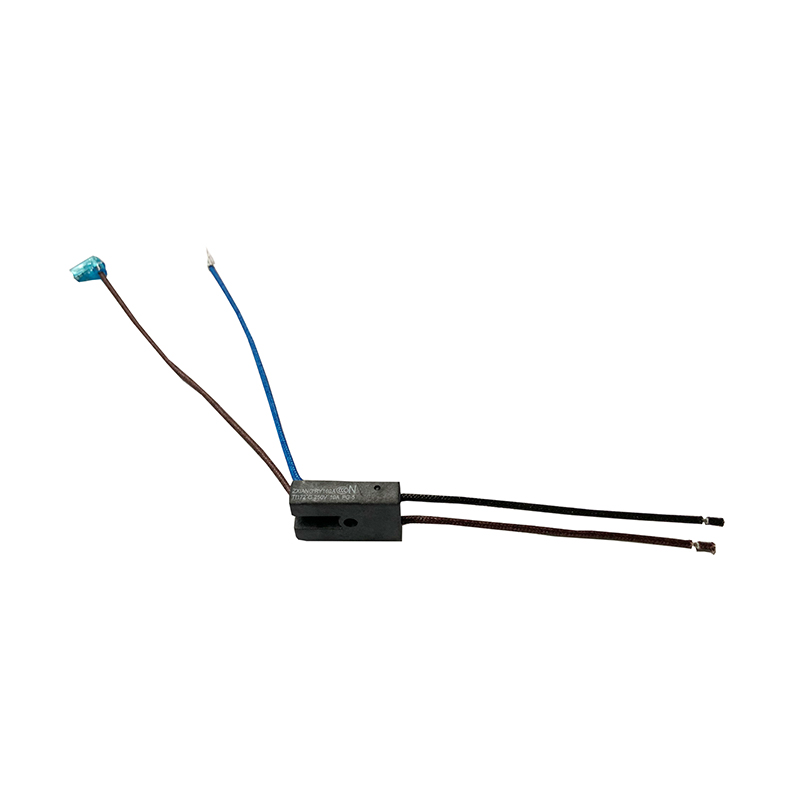

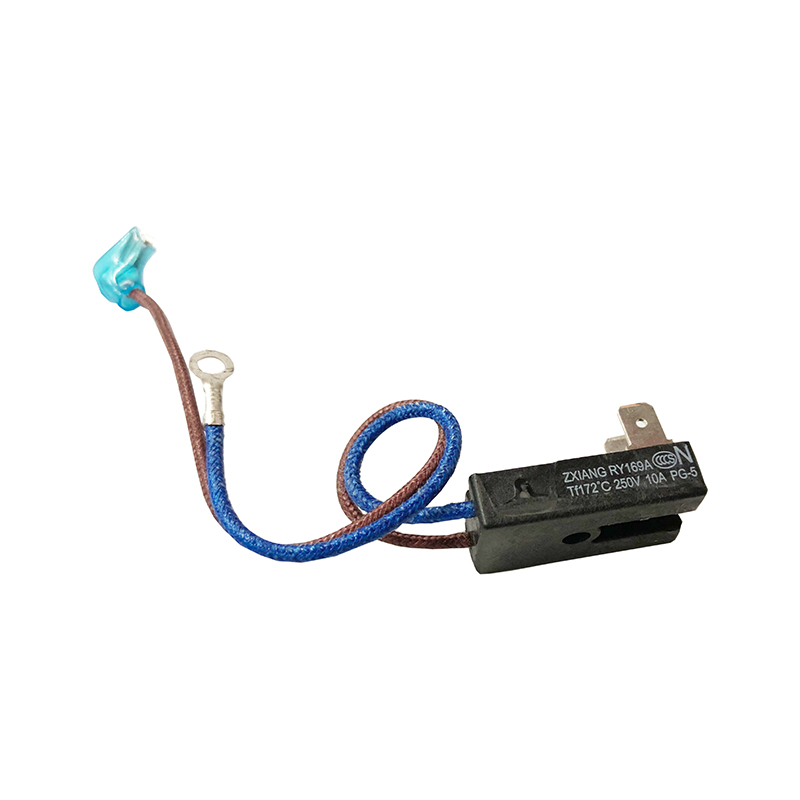

Thermal cut-off potting components are a device used for circuit protection, usually used to prevent circuit damage due to overheating. It protects the device by disconnecting the circuit when the temperature exceeds the set threshold through a thermal fuse. The potting process is used to encapsulate the components to enhance their mechanical strength and environmental adaptability.

Main features:

1. Thermal cut-off function: When the temperature exceeds the set value, the thermal fuse disconnects the circuit to prevent overheating.

2. Potting protection: Potting materials (such as epoxy resin) provide waterproof, dustproof, shockproof and other protections to improve the durability of the components.

3. High reliability: Suitable for harsh environments to ensure long-term stable operation.

4. Multiple specifications: Temperature thresholds and electrical parameters can be selected according to different needs.

Application areas:

- Household appliances: such as rice cookers, water heaters, etc., to prevent overheating and fire.

- Industrial equipment: used for motors, transformers, etc., to prevent overheating damage.

- Automotive electronics: protect circuits in high temperature environments.

- New energy: such as battery management systems to prevent battery overheating.

Selection points:

- Temperature threshold: Select the appropriate thermal fuse according to the operating temperature of the equipment.

- Electrical parameters: Ensure that the rated current and voltage meet the requirements.

- Potting material: Select temperature-resistant and chemical-resistant materials according to the environment.

- Size and installation: Ensure that the component size is suitable for the installation space.

Thermal fuse potting type components effectively protect the circuit through thermal fuse and potting technology, and are suitable for a variety of occasions requiring overheating protection.

English

English عربى

عربى Español

Español