Engineered for demanding environments, our UL1330/1331 certified fluoroplastic wires deliver unmatched reliability in high-temperature applications. With a 600V...

PTFE Insulated Wires Suppliers

-

-

UL1332/1333 Pep Teflon Polymer Insulated Plastic Wire

UL1332/1333 Pep Teflon Polymer Insulated Plastic WireEngineered for demanding environments, our UL1330/1331 certified fluoroplastic wires deliver unmatched reliability in high-temperature applications. With a 600V...

Teflon wire is a wire that uses polytetrafluoroethylene (PTFE) as an insulating material. PTFE is a high-performance plastic with excellent high temperature resistance, chemical corrosion resistance and electrical insulation properties. Therefore, Teflon wire is widely used in occasions that require high reliability and durability.

Main features

1. High temperature resistance: Teflon wire can work stably in the temperature range of -200°C to +260°C, suitable for high temperature environments.

2. Chemical corrosion resistance: PTFE is almost not corroded by any chemical substances and is suitable for corrosive environments.

3. Low friction coefficient: The surface is smooth and the friction coefficient is extremely low, which is suitable for applications that need to reduce friction.

4. Excellent electrical insulation performance: It has high dielectric strength and low dielectric constant, suitable for high frequency and high voltage applications.

5. Flame retardancy: PTFE is not easy to burn and has good flame retardant properties.

Application areas

1. Aerospace: Used in electrical systems in aircraft and spacecraft, requiring high reliability and high temperature resistance.

2. Electronics industry: used in high-frequency circuits, high-temperature circuits and occasions requiring high insulation performance.

3. Medical equipment: used in equipment that requires chemical corrosion resistance and high-temperature sterilization.

4. Chemical industry: used for electrical connections and sensors in corrosive environments.

5. Military and defense: used in military equipment with high reliability and durability requirements.

Notes

1. Processing difficulty: PTFE material processing is difficult and requires special processing technology.

2. High cost: Compared with ordinary wires, Teflon wires are more expensive.

Teflon wires are widely used in high-end industrial and scientific fields due to their excellent performance.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

Teflon Wire: A High-Performance Insulator for Electronics and Electrical Systems

Teflon wire, also known as PTFE insulated wire, has become a crucial component in industries that require high-performance materials capable of withstanding extreme conditions. Renowned for its exceptional properties, PTFE offers superior high-temperature resistance, chemical corrosion resistance, and outstanding electrical insulation characteristics. As a result, Teflon wire is widely utilized in electronics, electrical systems, aerospace, medical devices, and many other high-end industrial applications.

Key Features of Teflon Wire

The core strength of Teflon wire lies in the unique properties of polytetrafluoroethylene (PTFE), the material that makes up its insulation. PTFE is a high-performance plastic that offers exceptional resistance to extreme temperatures, chemicals, and wear. These features are particularly valuable in applications that demand both durability and reliability.

1. High-Temperature Resistance

Teflon wire can withstand temperatures ranging from -200°C to +260°C, making it highly suitable for high-temperature environments. This wide temperature tolerance enables Teflon wire to be used in industries such as aerospace and electronics, where components often operate under extreme thermal conditions. Whether exposed to the heat of an industrial oven or the cold of outer space, Teflon wire performs without compromising its integrity.

2. Chemical Corrosion Resistance

One of the standout features of PTFE is its near-immunity to chemical corrosion. Teflon wire is virtually unaffected by most chemicals, acids, and solvents. This makes it ideal for use in industries such as the chemical and medical fields, where electrical systems and components must be able to endure corrosive environments without breaking down.

3. Excellent Electrical Insulation

Teflon’s high dielectric strength and low dielectric constant make it an excellent insulator for electrical wiring. It allows for superior performance in high-frequency and high-voltage circuits. The electrical insulation properties of PTFE are particularly beneficial in sensitive applications such as aerospace systems, medical devices, and telecommunications equipment, where safety and reliability are paramount.

4. Low Friction Coefficient

The surface of PTFE is smooth and has a very low friction coefficient, which makes it ideal for applications where reduced friction is critical. This feature contributes to its use in machinery, robotics, and automotive systems where smooth movement and reduced wear are required.

5. Flame Retardancy

PTFE is inherently flame-retardant, which makes PTFE insulated wire suitable for applications that require high safety standards. Whether in electrical systems in spacecraft or within sensitive equipment, Teflon wire ensures that the risk of fire is minimized due to its non-flammable properties.

Applications of Teflon Wire

Due to its unparalleled features, Teflon wire is widely used in various industries, especially those requiring high reliability and durability. Let's explore some of the key sectors where Teflon wire is making a significant impact.

Aerospace Industry

The aerospace industry is one of the primary applications of Teflon wire. Given the critical nature of electrical systems in aircraft and spacecraft, the need for reliable components that can withstand extreme temperatures and environmental conditions is essential. Teflon wire excels in these environments, ensuring that electrical systems function flawlessly, even in the harshest conditions. With its resistance to both high temperatures and chemicals, Teflon wire is the go-to solution for aerospace applications where failure is not an option.

Electronics and Electrical Systems

In the electronics industry, where high-frequency circuits and high-voltage systems are common, Teflon wire is essential for maintaining performance and safety. The exceptional electrical insulation properties of PTFE make it a top choice for use in devices such as telecommunications equipment, computers, and power systems. Teflon wire not only ensures the reliability of electrical systems but also extends their lifespan by protecting them from damage due to environmental factors like heat and moisture.

Medical Equipment

In medical devices, where cleanliness and reliability are of utmost importance, Teflon wire is often the material of choice. Its chemical resistance makes it ideal for use in environments that require sterilization, such as in surgical instruments and diagnostic equipment. Furthermore, its ability to withstand high temperatures ensures that Teflon wire can continue to perform in autoclaves and other sterilization processes.

Chemical Industry

The chemical industry, where exposure to corrosive substances is common, benefits greatly from Teflon wire. PTFE’s resistance to acids, bases, and solvents makes Teflon wire a critical component in chemical plants, where it is used for wiring electrical connections and sensors in highly corrosive environments. With Teflon insulation, electrical systems can operate safely and efficiently, even when exposed to harsh chemicals.

Military and Defense

The military and defense sectors demand materials that meet the highest standards of durability and reliability. Teflon wire plays an important role in military equipment, where it is used in complex electrical systems that must function in extreme conditions. Whether in communications systems or weaponry, Teflon wire ensures the safety and performance of mission-critical equipment.

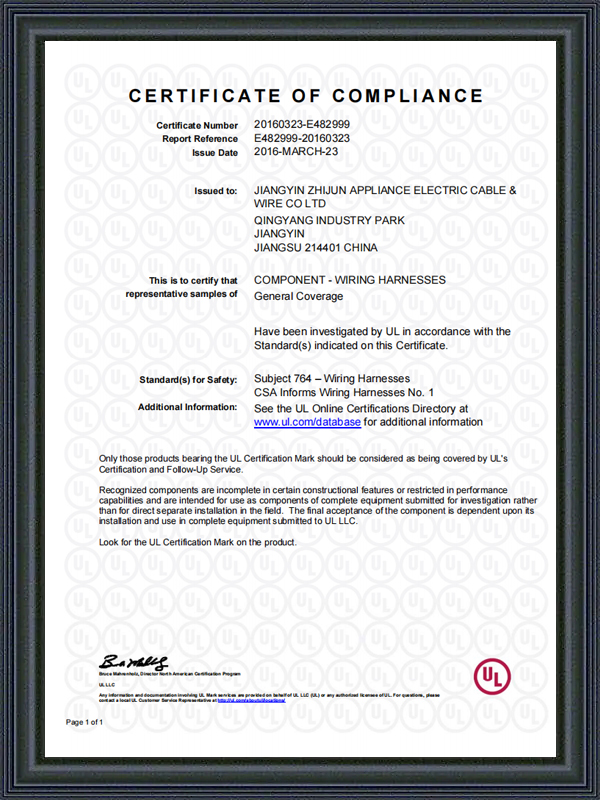

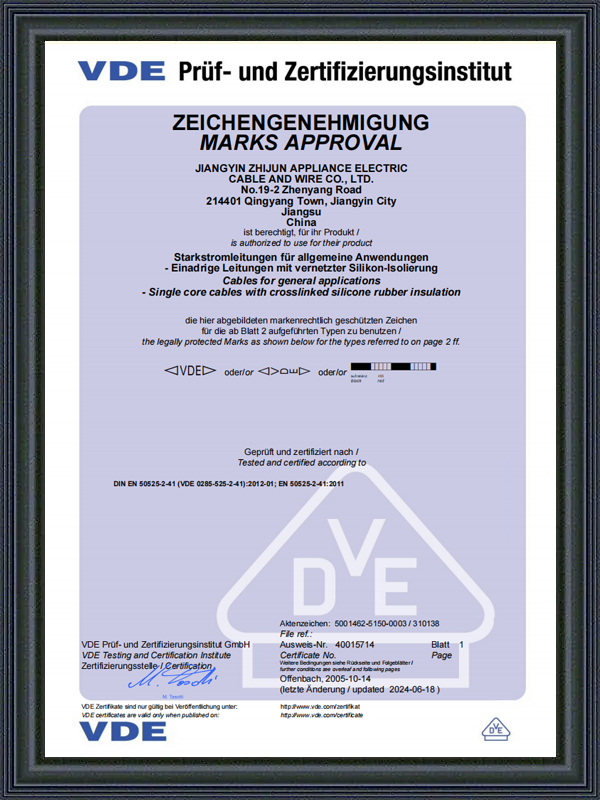

Manufacturing Excellence and Quality Assurance

At the heart of the Teflon wire industry lies advanced manufacturing technology and a focus on quality. Leading manufacturers of Teflon wire often operate large-scale facilities equipped with state-of-the-art production and testing equipment. These companies invest in cutting-edge research and development to create innovative solutions that meet the needs of industries ranging from electronics to aerospace.

The Future of Teflon Wire

The growing demand for reliable, high-performance materials across various industries ensures that Teflon wire will continue to be a vital component in many applications. As industries such as aerospace, electronics, medical devices, and chemical processing evolve, the need for materials capable of meeting increasingly demanding conditions will only rise. Teflon wire, with its impressive array of features, is poised to remain at the forefront of industrial wiring solutions.

In the coming years, we can expect further advancements in PTFE technology, making Teflon wire even more versatile and capable of meeting the needs of cutting-edge industries. As manufacturers continue to innovate and improve production methods, the applications of Teflon wire will expand, making it an even more indispensable material in modern engineering.

English

English عربى

عربى Español

Español