60245IEC03(YG) is a specific type of braided silicone wire, which is usually used for electrical connections in high temperature environments. Here is some basi...

Braided Silicone Rubber Wires Suppliers

-

-

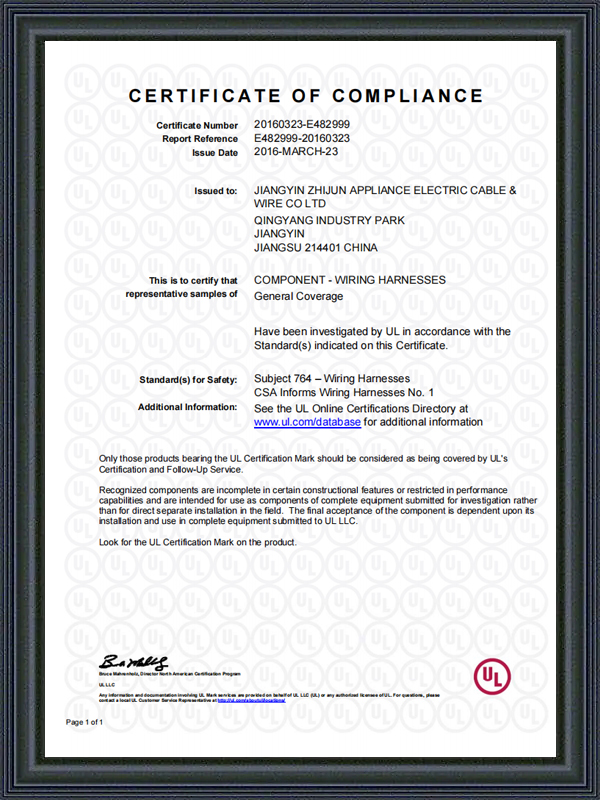

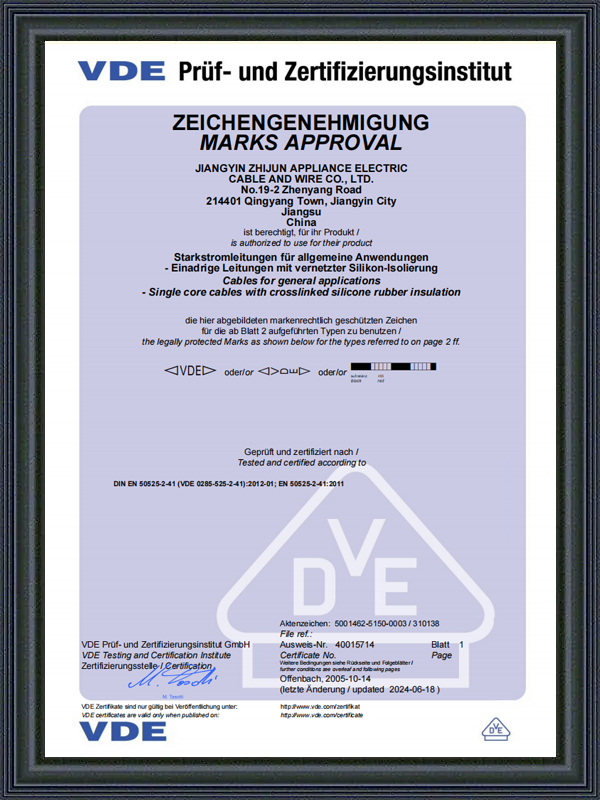

H05SJ-K Vde Certified Single Core Multi-Strand Tinned Copper Wire Silicone Wire

H05SJ-K Vde Certified Single Core Multi-Strand Tinned Copper Wire Silicone WireH05SJ-K is a glass fiber braided silicone rubber wire, usually used in high temperature environments or where high flexibility and chemical corrosion resistance...

-

UL3122 7-Core High Temperature Resistant Glass Fiber Braided Silicone Wire 18awg

UL3122 7-Core High Temperature Resistant Glass Fiber Braided Silicone Wire 18awgUL3122 is a wire made of glass fiber braid and silicone rubber insulation. Main features1. High temperature resistance: The silicone rubber insulation layer can...

-

UL3145 Silicone Wire and Cable

UL3145 Silicone Wire and CableUL3145 silicone wire and cable is the ultimate solution for high-demand electrical applications. Rated for 600V and 200°C , it delivers unmatched reliability in...

-

UL3172 Braided Silicone Insulated Wire

UL3172 Braided Silicone Insulated WireThe UL3172 braided silicone insulated wire combines rugged durability with exceptional thermal performance, making it the ultimate choice for harsh environments...

-

UL3071/3074/3075 With Braided Silicone Wire

UL3071/3074/3075 With Braided Silicone WireDesigned to perform under extreme conditions, this UL3071 3074 3075 with braided silicone wire offers a rated voltage of 600V and operates reliably at temperatu...

-

UL3144 Glass Fiber Silicone Wire

UL3144 Glass Fiber Silicone WireThe UL3144 Glass Fiber Silicone Wire is a premium electrical solution designed to excel in harsh environments. Featuring a 600V voltage rating and 150°C tempera...

-

UL3231 Glass Fiber Braided Silicone High Temperature Resistant Wire

UL3231 Glass Fiber Braided Silicone High Temperature Resistant WireUL3231 Glass fiber braided silicone high temperature resistant wire combines rugged durability with exceptional electrical performance, making it ideal for dema...

Glass fiber braided silicone rubber wire is a special wire and cable with a variety of excellent properties. It is widely used in high temperature, high humidity, corrosive environments and occasions requiring flexibility and durability. The following are its main features and uses:

Main features:

1. High temperature resistance: The silicone rubber insulation layer can withstand temperatures up to 180°C to 200°C, suitable for high temperature environments.

2. Corrosion resistance: Silicone rubber has good resistance to a variety of chemicals and is suitable for corrosive environments.

3. Flexibility: The wire is soft, easy to install and bend, and suitable for complex wiring.

4. High mechanical strength: The glass fiber braided layer enhances the tensile and wear resistance of the wire.

5. Excellent electrical properties: Good insulation performance, suitable for high voltage and high frequency occasions.

6. Weather resistance: Anti-ultraviolet, ozone and aging, suitable for outdoor use.

Application areas:

1. Industrial equipment: used for high temperature motors, heaters, industrial furnaces, etc.

2. Aerospace: Due to its high temperature resistance and corrosion resistance, it is often used in aircraft and spacecraft.

3. Automotive industry: used in high temperature environments such as engine compartments.

4. Household appliances: suitable for high temperature appliances such as electric blankets and ovens.

5. Medical equipment: used for medical equipment that requires high temperature disinfection.

6. New energy: used for solar and wind energy equipment, adapted to harsh outdoor environments.

Structure:

1. Conductor: usually copper or tinned copper, providing good conductivity.

2. Insulation layer: silicone rubber, high temperature resistant and flexible.

3. Braided layer: glass fiber, enhanced mechanical strength.

4. Outer sheath: silicone rubber or glass fiber braided for additional protection.

Notes:

- Installation: avoid excessive bending or stretching to prevent damage.

- Storage: store in a dry, cool place, avoid high temperature and humidity.

- Use environment: ensure that the ambient temperature is within the tolerance range of the wire.

This wire performs well in harsh environments such as high temperature and corrosiveness, and is an ideal choice for many industrial and special application scenarios.

-

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impractical. These specialized cables consist of resistance heating elements encased within flexible silicone rubber insulati...

READ MORE -

Introduction to PVC Wiring Installation PVC wiring installation plays a critical role in modern electrical and electronic systems. Polyvinyl chloride (PVC) insulated wires are widely used for residential, commercial, and industrial applications due to their flexibility, durability, and safety. Proper installation ensur...

READ MORE -

High temperature wire is a type of electrical wire designed to operate safely and reliably in environments where normal wiring would fail due to heat, chemical exposure, or extreme mechanical stress. These wires use specialized insulation materials and conductor designs to withstand sustained high temperatures, often r...

READ MORE

How Braided Silicone Rubber Wires Provide Superior Electrical Insulation for High-Frequency Applications?

Braided Silicone Rubber Wires are an essential part of modern electrical systems, especially when high-frequency operations are required. These wires, known for their excellent flexibility and insulation properties, are engineered to handle the challenges presented by high-voltage, high-frequency environments. Their ability to minimize electrical interference and ensure smooth signal transmission makes them the go-to solution for a variety of demanding applications, including aerospace, telecommunications, and industrial equipment.

One of the primary benefits of Braided Silicone Rubber cables is their outstanding electrical insulation performance. Unlike traditional materials, silicone rubber offers exceptional resistance to electrical breakdown, even under high-stress conditions. This is especially crucial in high-frequency applications where even the slightest signal disruption can cause significant system malfunctions. Silicone rubber's superior dielectric properties ensure that electrical signals flow uninterrupted, reducing the chances of energy loss or interference.

Another factor that makes Braided Silicone Rubber Wires highly sought after is their ability to withstand extreme temperatures. These cables maintain their performance even in temperatures ranging from -60°C to 200°C. This temperature resilience is vital in high-frequency systems that often generate heat, such as in motors, power generators, and aerospace equipment. The silicone rubber insulation protects the conductor from thermal damage, preventing degradation and maintaining consistent electrical properties over time.

Flexibility is another key characteristic that makes these wires perfect for high-frequency applications. The combination of silicone rubber and a braided glass fiber layer gives these wires a unique flexibility that is difficult to achieve with other materials. This flexibility ensures easy installation in tight spaces and around obstacles, making them ideal for complex wiring systems where maneuverability is essential. Whether in industrial machinery or precision electronics, these cables offer the flexibility needed to adapt to intricate layouts.

Braided silicone rubber cables also provide superior mechanical strength. The braided glass fiber layer enhances the wire's tensile strength, allowing it to endure high mechanical stresses. This feature is particularly important in systems where wires are subject to constant movement or vibration, such as in robotics, automotive systems, and heavy-duty machinery. By preventing stretching or breaking under pressure, these cables ensure the longevity and reliability of your equipment.

The ability of these wires to resist aging, UV rays, and ozone exposure adds another layer of protection, particularly for outdoor applications. As high-frequency systems often operate in environments where wires are exposed to the elements, durability against weathering is essential. Silicone rubber’s weather resistance helps the wires maintain their performance even after prolonged exposure to harsh conditions, ensuring that they continue to function as intended without significant degradation.

In addition to their robustness in extreme environments, Braided Silicone Rubber Wires also excel in their ability to handle high-frequency signals. High-frequency systems, like those in telecommunications, aerospace, and military equipment, require precise and consistent transmission. The insulation properties of silicone rubber minimize signal distortion, allowing for high-quality, interference-free communication. This makes these wires a preferred choice for circuits that need to maintain signal integrity and prevent electromagnetic interference (EMI).

Safety is another reason why silicone rubber cables are widely used in sensitive applications. Silicone rubber is non-toxic and flame-resistant, making it ideal for use in critical settings where safety is a top priority. In high-frequency electrical systems where the risk of heat buildup is elevated, having a non-flammable insulation material adds an extra layer of protection, preventing potential fire hazards that could result from electrical failures.

If you're looking to ensure the efficiency and longevity of your electrical systems, choosing the right wire is critical. Braided Silicone Rubber Wires offer not only the electrical insulation needed for high-frequency operations but also the durability, flexibility, and safety required for reliable performance. They help maintain system integrity over time, reducing maintenance costs and ensuring that your equipment stays operational in even the most demanding environments.

These cables are more than just a component of your wiring system—they are an investment in the long-term success of your electrical infrastructure. From high-frequency machines to aerospace applications, choosing Braided Silicone Rubber cables means you’re opting for a proven solution that will enhance the reliability and safety of your systems. So, whether you’re looking to upgrade your current setup or design a new one, these wires are the ideal choice for high-performance and durable electrical systems.

By understanding the full range of benefits that Braided Silicone Rubber Wires bring to high-frequency applications, you’ll be better equipped to make an informed decision for your next project. Choose the right materials, and you’ll ensure the optimal performance and longevity of your electrical systems for years to come.

English

English عربى

عربى Español

Español