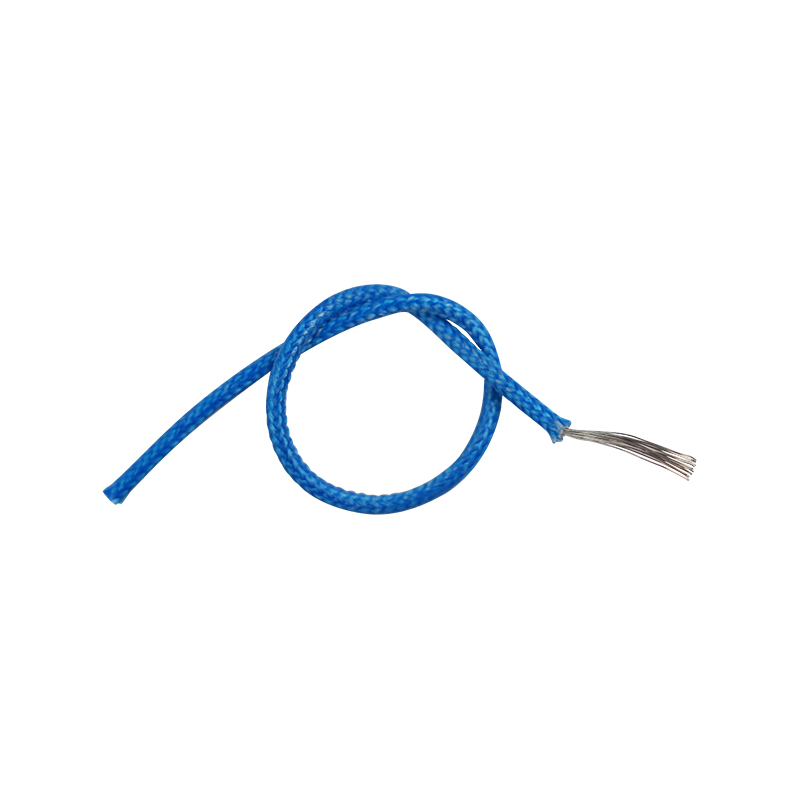

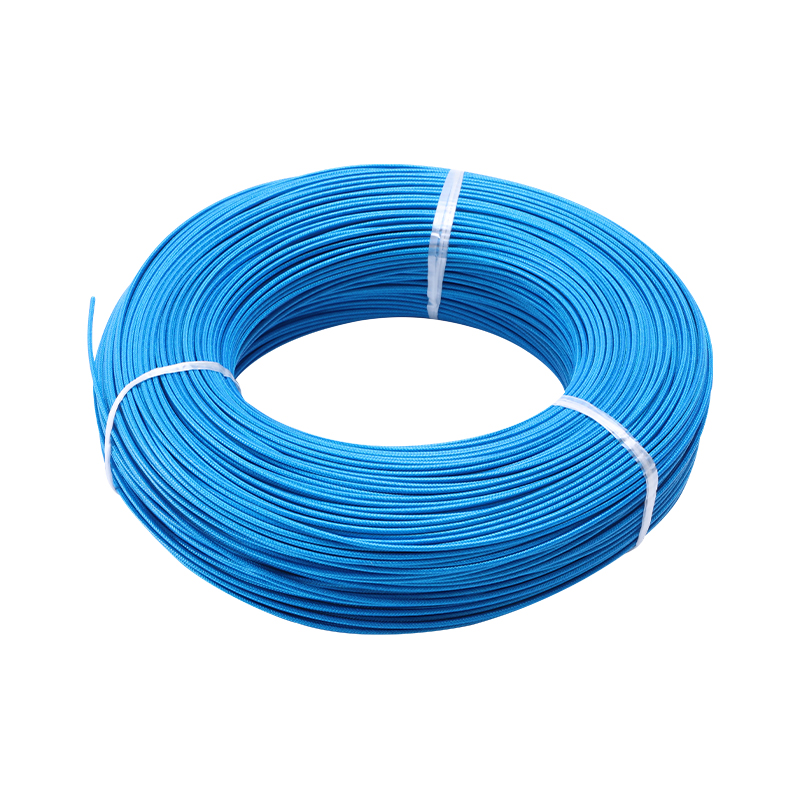

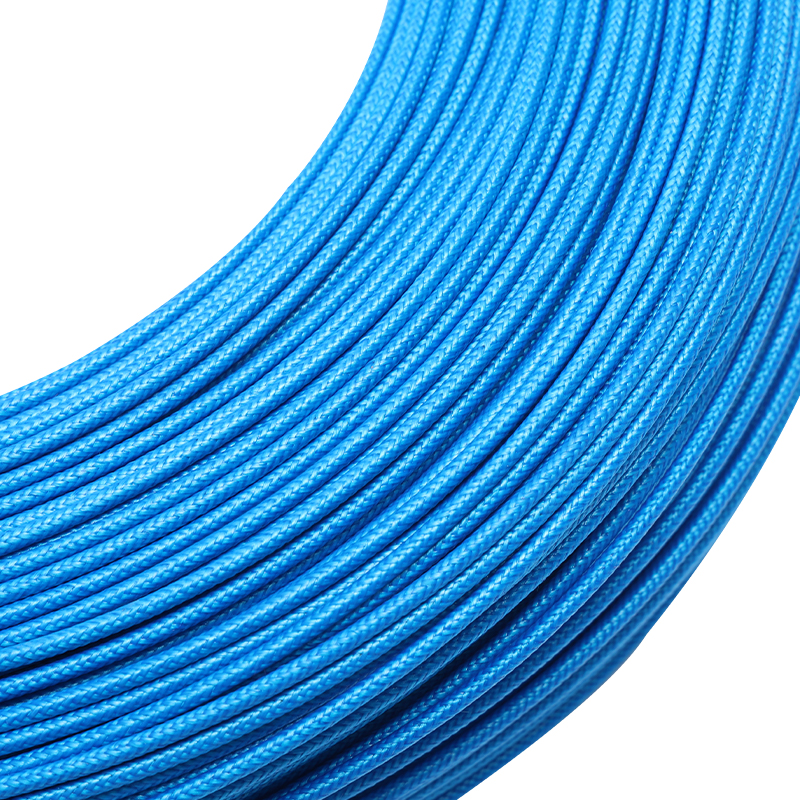

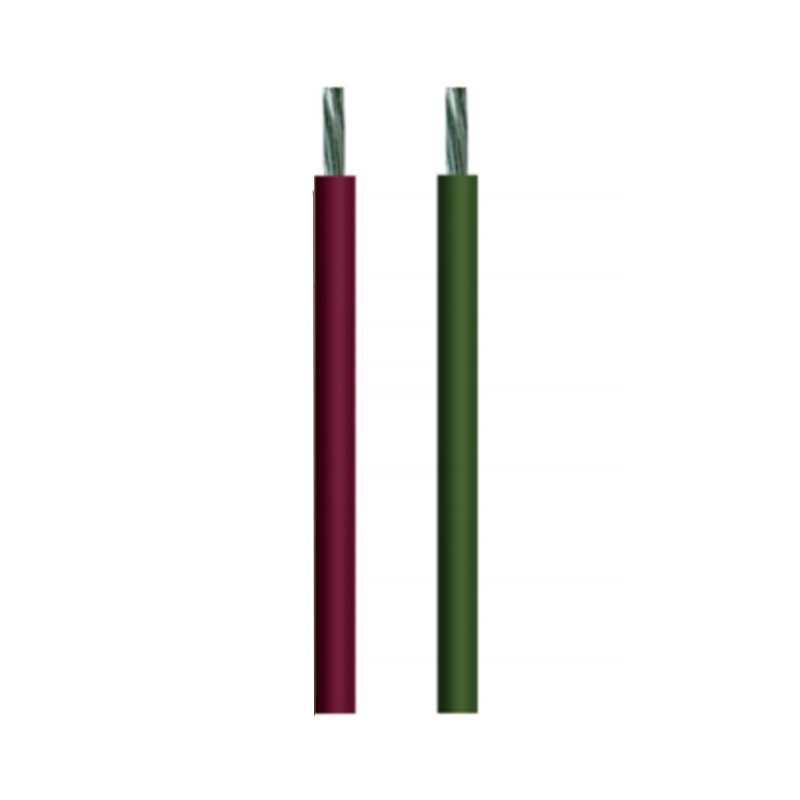

UL3231 Glass fiber braided silicone high temperature resistant wire combines rugged durability with exceptional electrical performance, making it ideal for demanding industrial applications. Featuring a 600V voltage rating and resistance to extreme temperatures (150°C / 200°C ), this silicone-insulated wire ensures reliable operation in harsh environments, from industrial ovens to heavy machinery. The glass fiber braid adds superior mechanical protection and thermal stability, while the flexible silicone jacket resists abrasion, chemicals, and moisture.Available with versatile conductor options—bare steel, tinned, silver-plated, or nickel-plated copper —it adapts to diverse needs, offering corrosion resistance and optimal conductivity.Choose UL3231 for unmatched reliability in extreme heat, vibration, and corrosive conditions—engineered to last where others fail.

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impra...

READ MORE

English

English عربى

عربى Español

Español