UL3122 is a wire made of glass fiber braid and silicone rubber insulation.

Main features

1. High temperature resistance: The silicone rubber insulation layer can withstand temperatures up to 200°C.

2. Chemical corrosion resistance: Good resistance to chemicals such as oil, acid, and alkali.

3. Flexibility: The glass fiber braid enhances the flexibility and mechanical strength of the wire.

4. Electrical properties: With good insulation and electrical properties, it is suitable for a variety of electrical applications.

5. Flame retardant: Meets UL standards and has flame retardant properties.

Application areas

1. Industrial equipment: used for motors, transformers, etc. in high temperature environments.

2. Household appliances: Suitable for high temperature appliances such as ovens and microwave ovens.

3. Automotive industry: Used for wiring in high temperature areas such as engine compartments.

4. Aerospace: Used for high temperature and corrosion resistant electrical connections.

5. Medical equipment: Used for medical instruments that require high temperature sterilization.

Technical Parameters

- Rated temperature: -60°C to +200°C

- Rated voltage: Typically 600V

- Conductor material: Tinned copper or bare copper

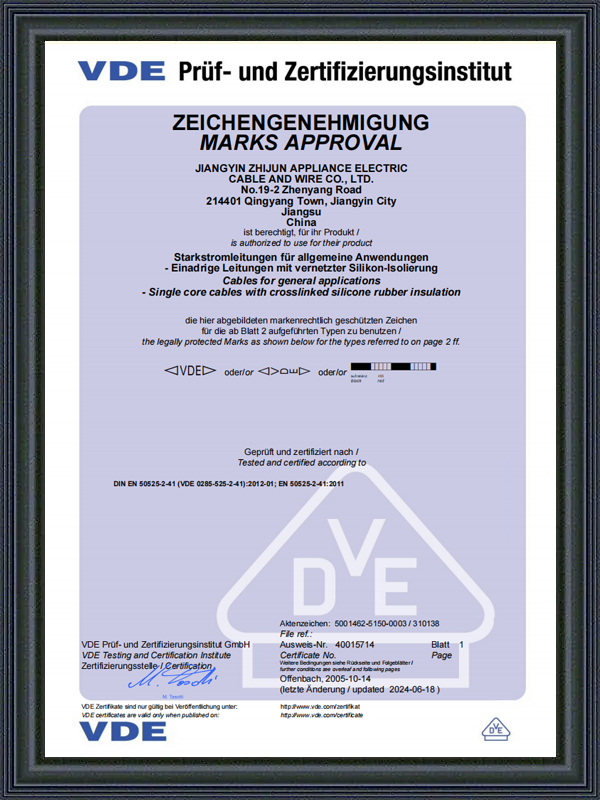

- Insulation material: Silicone rubber

- Outer sheath: Glass fiber braid

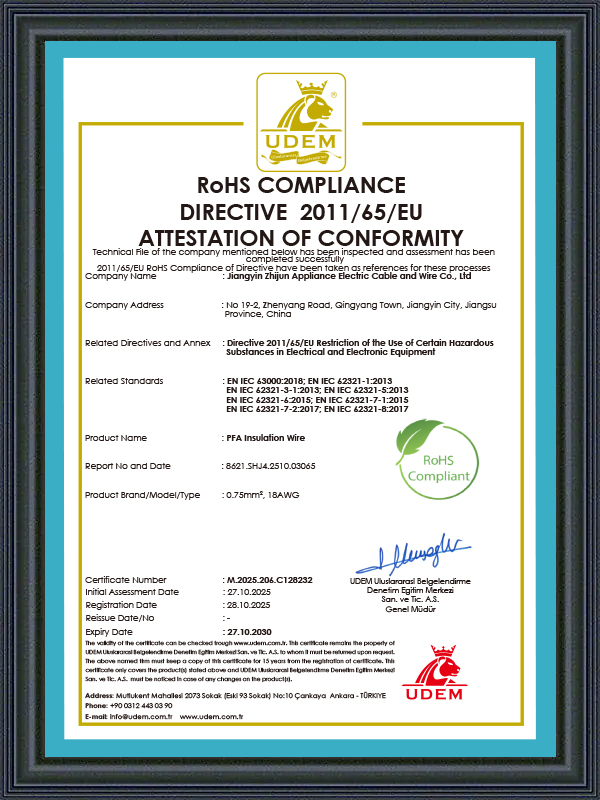

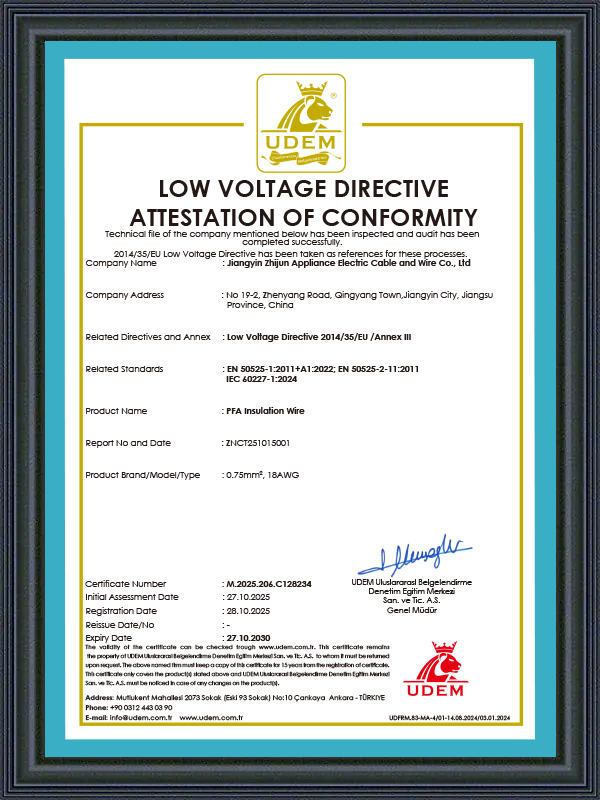

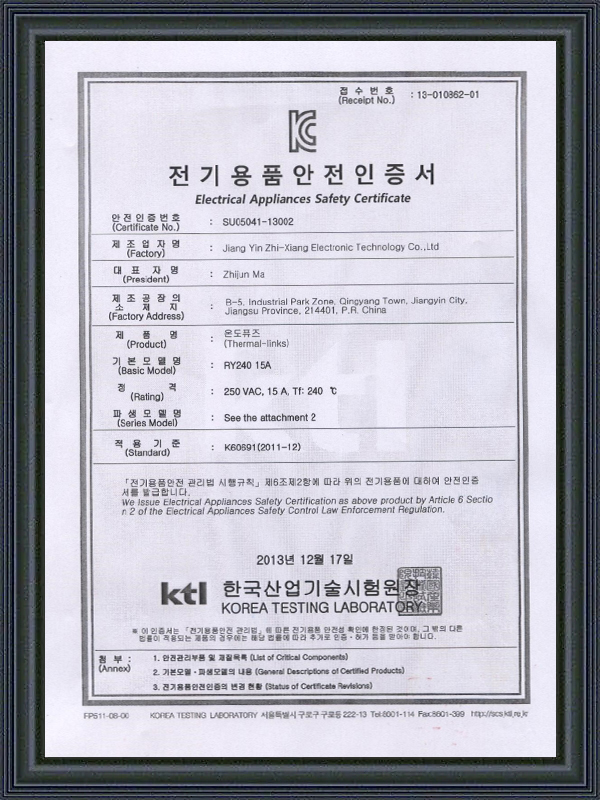

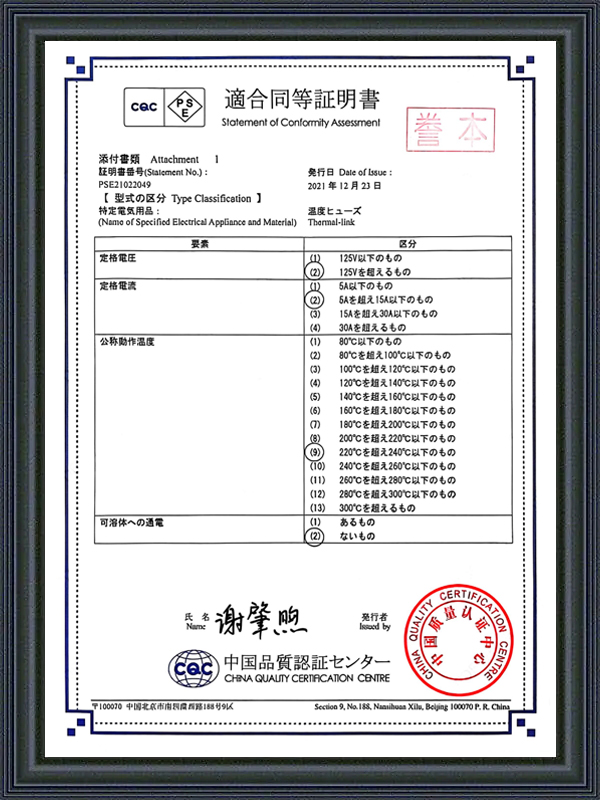

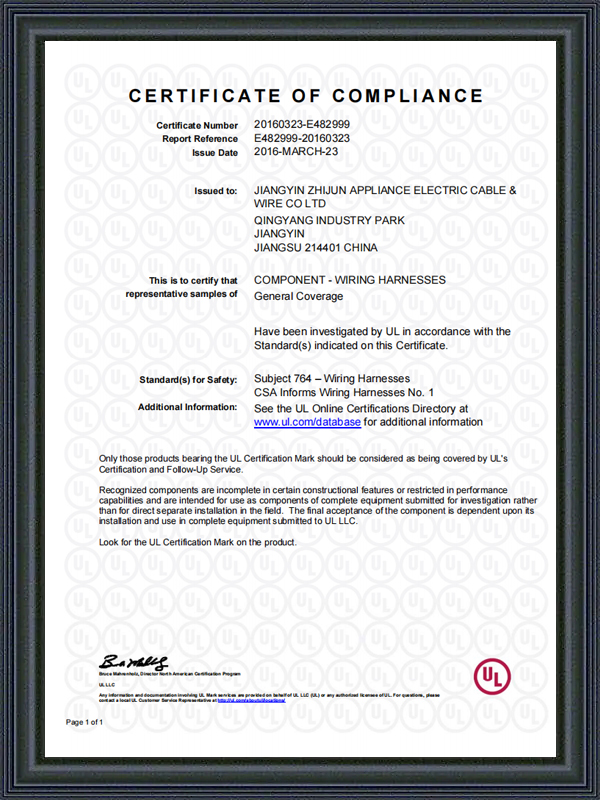

Standard certification

- UL certification: Meets UL3122 standard to ensure safety and reliability.

Precautions

- Installation environment: Avoid excessive bending or mechanical damage.

- Storage conditions: Store in a dry, cool place, away from direct sunlight and high temperature.

UL3122 wires are widely used in a variety of harsh environments due to their high temperature resistance and chemical corrosion resistance.

English

English عربى

عربى Español

Español