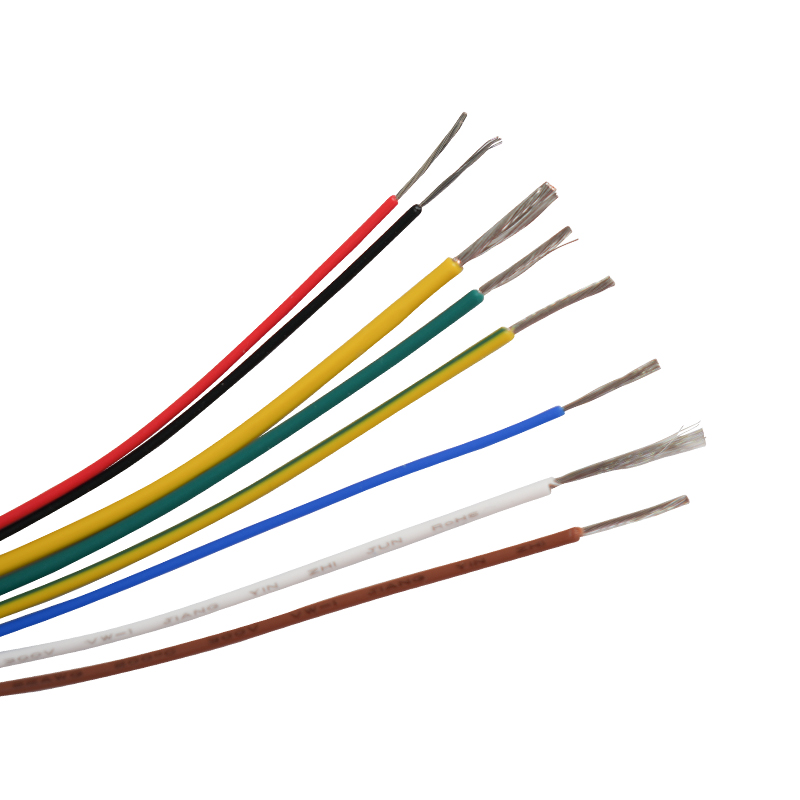

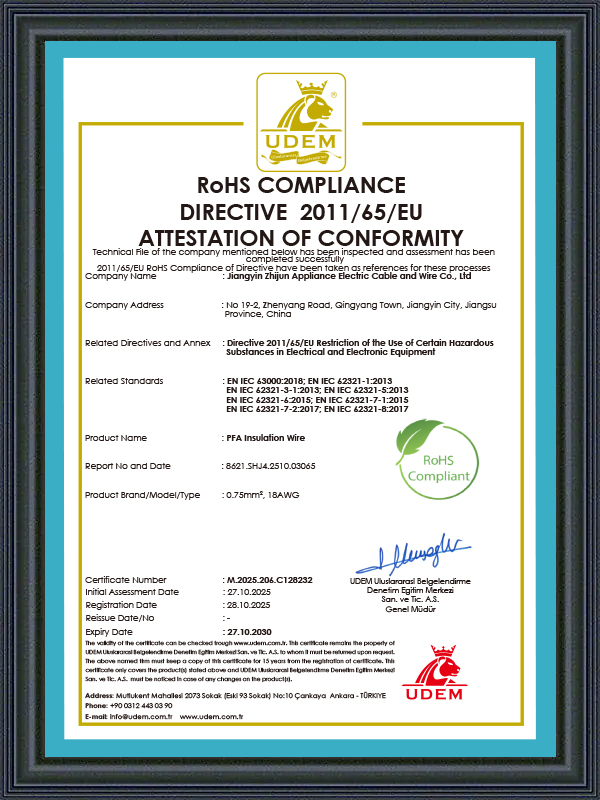

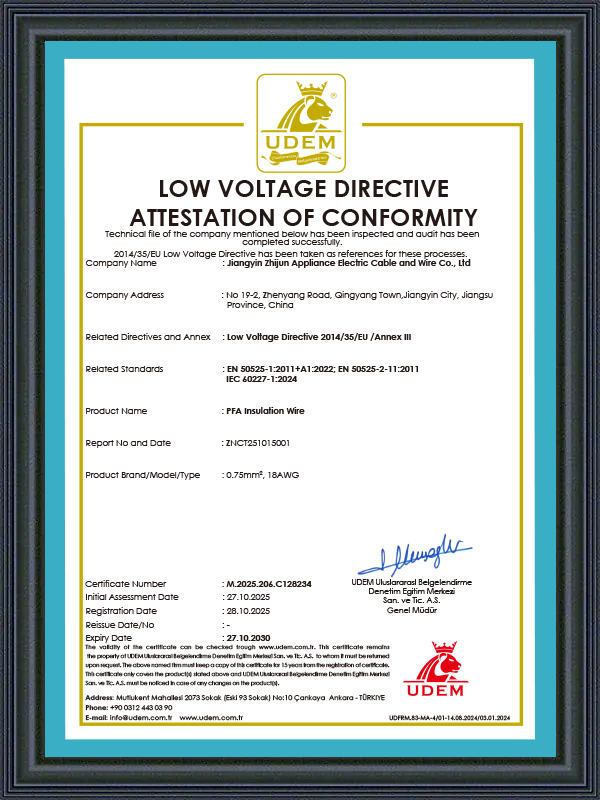

UL3139 certification standard: UL758, certification number: E301946 Rated voltage: 600V, suitable for low-voltage electrical equipment. Can it withstand a certain voltage shock. It has good flame retardant properties and complies with UL standards and Rohs directives. The conductor is made of bare copper or tinned copper, and can be a single-strand or multi-strand twisted structure. Multi-strand twisted is softer and suitable for applications that require frequent bending. The insulation layer is silicone rubber, which can usually withstand a continuous operating temperature of 200°C. Various colors and clear markings. Suitable for industrial, medical, lighting and other places, conductor specifications: 0.5mm²~240mm², 26awg~12awg

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impra...

READ MORE

English

English عربى

عربى Español

Español