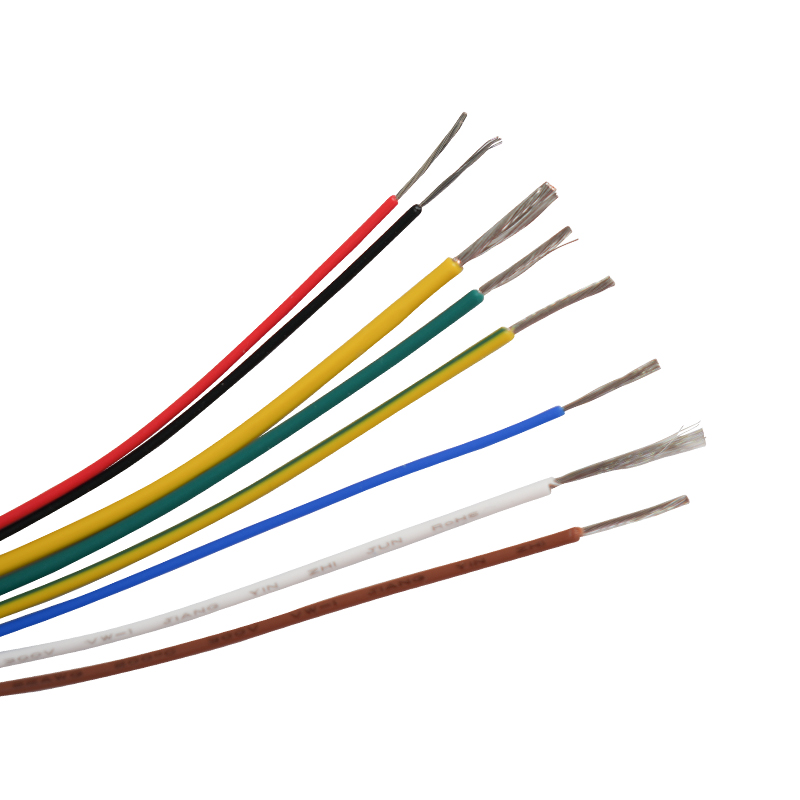

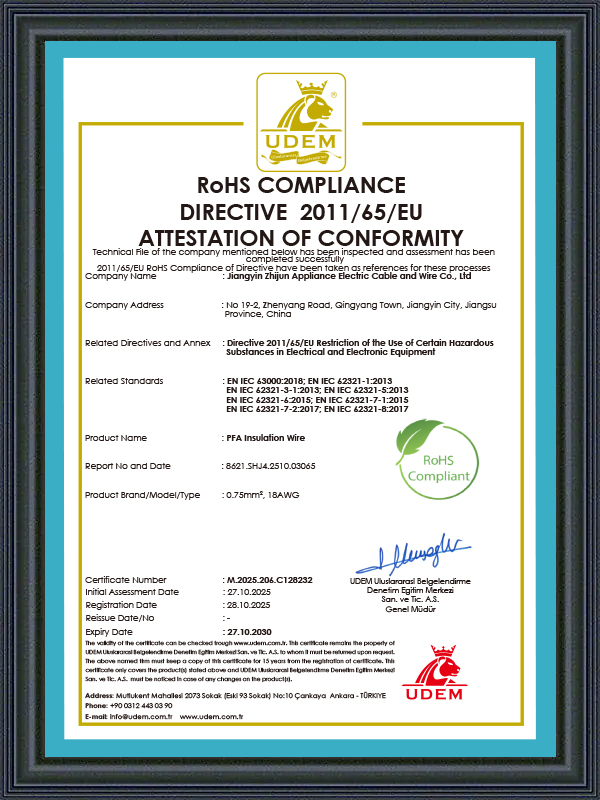

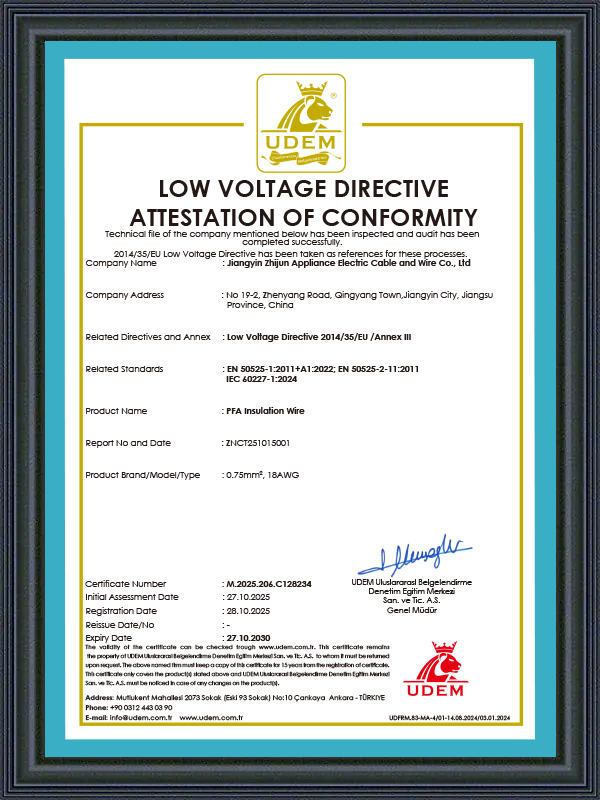

UL3239 has a temperature resistance of 200°C, a rated voltage of up to 10000V, a flame retardant grade of VW-1, and complies with the Rohs directive and does not contain hazardous substances. The production specifications range from 24-10AWG, solid stranded, and a conductivity of not less than 90%. The copper conductor can be tinned, silver-plated or nickel-plated. It is characterized by resistance to aging, ozone and chemical corrosion. It has good flexibility and is easy to install and wire. It is used in industrial heating equipment, electric heating appliances, motors, transformers, etc. It can also be used in medical equipment, aerospace, automotive electronics and other fields that require high cable performance. Common colors include black, red, white, yellow, green, etc., which are easy to distinguish circuits.

Silicone heating cables represent a sophisticated thermal management solution designed to deliver consistent, reliable heat in environments where conventional heating systems prove inadequate or impra...

READ MORE

English

English عربى

عربى Español

Español